Discover the Importance of Stepper Motor Weight for Optimal Performance

By:Admin

[Company Name], a leading manufacturer in the field of motion control technology, is revolutionizing the industry with its innovative and lightweight stepper motors. These cutting-edge devices are designed to provide precise control and high performance in a wide range of applications. With their compact size and impressive weight reduction, [Company Name]'s stepper motors are set to transform various industries, from robotics to aerospace.

Stepper motors play a crucial role in many industries by converting digital pulses into rotational motion. They are widely used in applications that require precise positioning, such as 3D printing, CNC machines, and automated manufacturing systems. Traditionally, stepper motors were known for their substantial weight, which limited their use in certain fields. However, [Company Name] has addressed this issue by utilizing advanced engineering techniques and materials to significantly reduce the weight of their motors.

One of the key advantages of [Company Name]'s stepper motors is their compact and lightweight design. By employing state-of-the-art manufacturing processes, the company is able to create motors that are up to 30% lighter than conventional options without compromising on performance or durability. This breakthrough is particularly beneficial in applications where weight reduction is essential, such as drones and satellite systems.

The weight reduction achieved by [Company Name] is made possible through the use of lightweight materials and advanced design optimizations. The company has developed proprietary techniques for making the motor components more efficient, resulting in a significant reduction in overall weight. By analyzing the structural integrity of each component and finding the optimal balance between weight and strength, [Company Name] has achieved a powerful yet lightweight motor design.

Apart from their weight advantage, [Company Name]'s stepper motors offer exceptional precision and accuracy. These motors utilize a unique step-by-step motion control system, where each step corresponds to a fixed angle of rotation. This allows for precise control and fine-tuning of the motor's movements. With their high torque and reliable positioning, [Company Name]'s stepper motors ensure smooth operation and exceptional performance in various applications.

Furthermore, [Company Name] places great emphasis on quality and reliability. All their stepper motors undergo rigorous testing and quality control measures to ensure they meet the highest industry standards. Customers can rely on [Company Name]'s motors to deliver consistent and dependable performance, even in demanding environments. This commitment to excellence has earned [Company Name] a reputation as a trusted supplier in the motion control industry.

The applications for lightweight stepper motors are vast and diverse. In the field of robotics, these motors enable more agile and maneuverable robots, allowing for precise control of movements and actions. Industries such as medical equipment manufacturing and automated laboratory systems can benefit from the compact and lightweight design of [Company Name]'s stepper motors, as they require precise positioning in confined spaces. Additionally, the aerospace industry can take advantage of these motors in the development of unmanned aerial vehicles (UAVs) and satellite systems, where weight reduction is critical for optimal performance.

As [Company Name] continues to innovate and push the boundaries of motion control technology, their lightweight stepper motors are set to leave a lasting impact on numerous industries. With their compact size, substantial weight reduction, and exceptional performance, these motors represent a new era of precise control and versatility. Expect to see more groundbreaking developments from [Company Name] as they strive to reshape the future of motion control technology.

Company News & Blog

Ultimate Guide to Nema 23 Stepper Motors: Everything You Need to Know

Title: Cutting-edge Nema 23 Stepper Motor Revolutionizes Industrial AutomationIntroduction:In the rapidly evolving field of industrial automation, one notable player has emerged with groundbreaking technology that is set to revolutionize the industry. The Nema 23 Stepper Motor, developed by a leader in electrical components manufacturing, is proving to be a game-changer in terms of its exceptional performance, efficiency, and durability. With its innovative features and broad range of applications, this motor is reshaping automation processes across multiple industries.Unleashing Unmatched Performance:The Nema 23 Stepper Motor boasts unprecedented performance capabilities that outshine competitors. With a high torque-to-inertia ratio and precise control over motion, this motor effortlessly handles rigorous and demanding industrial applications. Its ability to provide accurate position control without feedback sensors makes it ideal for tasks requiring precision and repeatability, such as 3D printers, CNC machines, and robotics.Efficiency Redefined:The incorporation of advanced manufacturing processes has endowed the Nema 23 Stepper Motor with unrivaled efficiency. By utilizing state-of-the-art materials and optimized design techniques, this motor offers reduced power consumption, resulting in lower operating costs for industrial applications. The motor's energy-saving capabilities make it an environmentally friendly choice, aligning with the growing global focus on sustainability.Engineered for Reliability:Recognizing the critical importance of reliability in industrial automation, the Nema 23 Stepper Motor is engineered to provide consistent and dependable performance, even in demanding environments. Its robust construction ensures resistance to vibrations, shocks, and extreme temperatures, making it suitable for deployment in a wide range of industrial settings. The motor's extended service life and minimal maintenance requirements contribute further to its appeal among industrial operators.Versatility across Industries:The Nema 23 Stepper Motor's versatility makes it a go-to solution for automation needs across diverse industries. From automotive manufacturing to medical equipment, its adaptability allows for seamless integration into various applications. The motor's ability to handle different load capacities and perform with exceptional precision makes it an invaluable asset for tasks such as material handling, sorting machines, and robotic assembly lines.User-Friendly Integration:Ensuring a hassle-free integration process, the Nema 23 Stepper Motor is designed with user-friendliness in mind. Its standardized dimensions and connections enable straightforward replacement of older motor models, minimizing downtime during implementation. Additionally, the motor's compatibility with numerous control systems and software further simplifies the integration process, facilitating a swift transition to enhanced automation capabilities.Future-Proofing Industrial Automation:The Nema 23 Stepper Motor is not just a solution for the present but is poised to meet the demands of future industrial automation advancements. As technological innovations continue to reshape the industrial landscape, this motor's inherent adaptability can accommodate emerging automation requirements. By offering a future-proof solution, the Nema 23 Stepper Motor enables industries to stay ahead in the fast-paced automation race.Conclusion:The Nema 23 Stepper Motor is an outstanding feat of engineering that has redefined the very essence of industrial automation. With its exceptional performance, efficiency, durability, and versatility, this motor is poised to drive a significant shift in the industry. As businesses strive for enhanced automation capabilities while emphasizing sustainability and reliability, the Nema 23 Stepper Motor stands as an ideal solution to meet their evolving needs. It is indeed a technological marvel that ensures businesses can embrace automation with confidence.

New High-Performance Gear Ratio Diameter Enhances Industrial Efficiency in China

Title: China's Latest Gear Ratio Diameter Revolutionizes Industrial ProcessesIntroduction:China, at the forefront of technological advancements, has introduced a groundbreaking gear ratio diameter that is set to redefine industrial processes. With a strong focus on innovation and cutting-edge manufacturing capabilities, Chinese companies have led the way in developing this game-changing gear technology. By efficiently maximizing power transmission, optimizing system performance, and improving overall productivity, this innovation is poised to catapult Chinese industries into a new era of growth and competitiveness. Gear Ratio Diameter: Revolutionizing Industrial Efficiency:The recently developed gear ratio diameter holds immense potential to revolutionize industrial efficiency across various sectors. Backed by extensive research and development, this gear technology is designed to enhance power transmission efficiency, reduce energy consumption, and ensure high levels of precision in industrial applications. Chinese manufacturing companies have duly acknowledged the importance of gear systems in enhancing overall productivity. Through the implementation of this gear ratio diameter, businesses can drive improvements in processes that rely on power transmission, such as automotive manufacturing, heavy machinery production, marine propulsion, and many others. This technology allows for the customization of gear systems to optimize torque requirements, resulting in significant cost savings and greater operational efficiencies.Furthermore, this advanced gear technology boasts the ability to minimize friction, reduce noise levels, and improve overall gear system performance. With better gear synchronization, industries can expect reduced downtime, enhanced reliability, and increased machine longevity. The Competitive Edge:China, being one of the global leaders in manufacturing, has recognized the significance of investing in innovative technologies to solidify its competitive edge. Chinese companies have transformed their gear manufacturing capabilities to ensure that the gear ratio diameter fulfills the dynamic needs of industries both nationally and internationally. By making use of advanced manufacturing techniques, such as CNC machining, automation, and precise quality control processes, Chinese manufacturers have achieved unparalleled levels of precision in gear production. This precision is crucial for the successful implementation of the gear ratio diameter, as even minor deviations can compromise the efficiency and performance of the system.Moreover, Chinese manufacturers have also focused on applying high-quality materials and rigorous testing processes to ensure the durability and longevity of their gear systems. This commitment to quality has allowed Chinese companies to gain the trust of domestic and international customers, solidifying their position as reliable suppliers of gear transmission solutions.Global Adaptation:The introduction of the gear ratio diameter technology by Chinese companies has received global attention and acclaim. Many international businesses, including those operating in developed countries with established industrial sectors, are recognizing the immense benefits of incorporating this gear technology into their operations.The ease of adaptability and customization provided by the gear ratio diameter technology is a key factor that attracts businesses from all corners of the globe. By offering tailor-made gear systems, Chinese manufacturers can accommodate specific industrial requirements, ensuring maximum efficiency and performance for each unique application.Additionally, the cost-effectiveness of these gear systems also appeals to international businesses. With Chinese manufacturers offering competitive pricing without compromising on quality, foreign industries can achieve significant cost savings while embracing cutting-edge technology.Future Outlook:Looking ahead, the development and implementation of the gear ratio diameter technology will continue to drive China's industrial growth and development. With a strong commitment to investing in research and development, Chinese manufacturers are poised to push the boundaries of gear technology even further.As industries across the globe seek ways to boost efficiency and productivity, Chinese gear systems are poised to become an essential component of their operations, ensuring seamless power transmission and maximum reliability. Chinese manufacturers will likely continue to innovate and refine gear systems to meet evolving industry demands and cement their position as leaders in the worldwide market.Conclusion:China's gear ratio diameter technology represents a significant milestone in the industrial sector. Its ability to optimize power transmission, enhance precision, reduce energy consumption, and provide cost-effective solutions has made it highly sought after globally. Backed by Chinese manufacturers' commitment to quality, adaptability, and manufacturing excellence, this gear technology is set to shape the future of industrial processes, positioning China at the forefront of global manufacturing innovation and competitiveness.

Compact DC Motors for Various Applications: A Overview

Title: Small DC Motor Manufacturers Innovate with Reliable and Efficient SolutionsIntroduction:The small DC motor industry plays a significant role in a wide range of applications across various sectors. Among the market leaders, one company stands out for its commitment to innovation, superior quality, and relentless pursuit of reliability and efficiency. With an unwavering focus on meeting customer demands, this company, known for its OEM small DC motor production, continues to set benchmarks in the industry.Company Profile:This leading company, with decades of expertise in small DC motor manufacturing, has an impressive track record for designing and producing top-notch components. Drawing from a strong foundation in engineering and industrial design, the company's core principles include cutting-edge technology, continuous research and development, exceptional manufacturing capabilities, and an unwavering commitment to quality assurance.Innovation to Drive Efficiency:Recognizing the increasing demand for reliable and energy-efficient solutions, the company invests heavily in research and development. By staying at the forefront of emerging technological trends, they consistently introduce innovative features to their small DC motor range.Among the key areas of focus for innovation are reducing power consumption, improving torque output, and enhancing overall motor efficiency. This dedication to efficiency not only benefits the end-users but also promotes sustainability by reducing energy waste.Quality Assurance:The company meticulously adheres to stringent quality control measures throughout the production process. With state-of-the-art testing facilities and a team of highly skilled engineers, each small DC motor undergoes rigorous testing to ensure longevity, reliability, and performance.By employing advanced quality management systems, the company maintains an unmatched level of precision and consistency. These measures ensure that their small DC motors meet or exceed industry standards, earning the trust and loyalty of customers worldwide.Diverse Applications:The company's OEM small DC motors find wide applications across numerous industries. Their motors power everything from household appliances and office equipment to automotive systems and medical devices. The versatility of their small DC motors is a testament to the company's ability to design tailor-made solutions that cater to diverse customer needs.The reliability and precision of these small DC motors make them ideal for critical applications where performance and durability are of utmost importance. Industries such as robotics, aerospace, telecommunications, and industrial automation rely on these motors to drive their operations efficiently.Global Reach:With a customer-centric approach and a robust distribution network, the company has established a strong global presence. Their dedication to customer satisfaction is reflected in their ability to provide tailored solutions to clients across various geographic locations.The company's strong market presence is further strengthened by its commitment to prompt deliveries, easy accessibility, and excellent after-sales service. By partnering with international distributors and local agents, they ensure that their small DC motors are available to customers worldwide, truly living up to their reputation as a global leader in the industry.Conclusion:As OEM small DC motor manufacturers, this industry-leading company continues to set new benchmarks through its relentless pursuit of reliability and efficiency. Their commitment to innovation, exceptional manufacturing capabilities, and adherence to stringent quality control measures have made their motors the go-to choice for a myriad of industries.With a firm focus on sustainability, customer satisfaction, and global market reach, this company ensures that their small DC motors remain at the forefront of cutting-edge technology. By combining innovation, precision, and versatility, they remain the premier choice for those seeking reliable and efficient solutions in the small DC motor market.

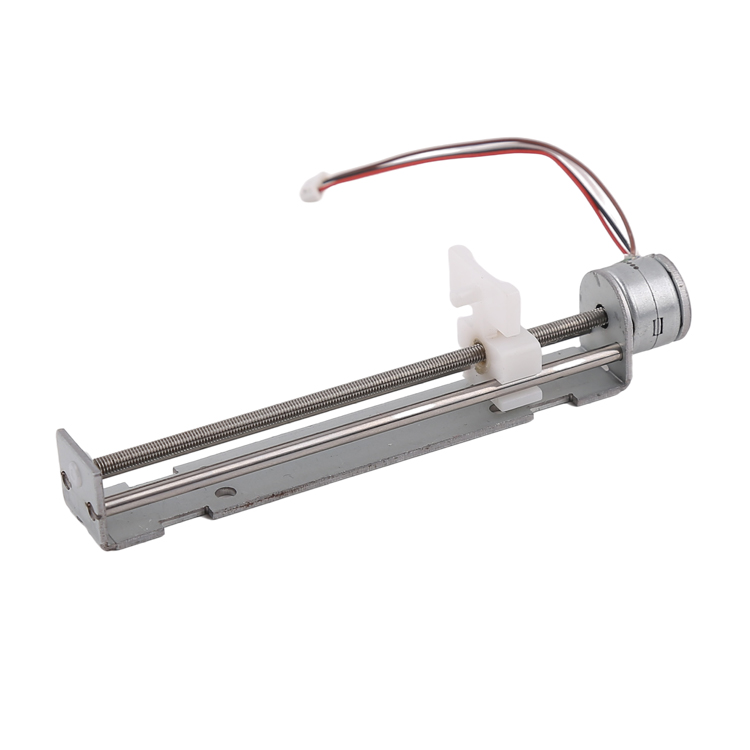

Compact Stepper Motor with Linear Motion for Precise Control

[Company Introduction]Founded in [year], [Company Name] is a leading manufacturer and supplier of advanced automation solutions. With our commitment to innovation and quality, we have been serving various industries globally, providing cutting-edge technologies to meet the evolving demands of our customers.Our extensive product portfolio includes a wide range of motors, controllers, drivers, and sensors that are designed to enhance precision, efficiency, and reliability in automation processes. We continuously invest in research and development to push the boundaries of technology, ensuring our customers have access to the most advanced solutions in the market.[Company Name] is dedicated to delivering excellent customer service, providing comprehensive technical support, and fostering long-term partnerships. Our team of highly skilled engineers and technicians are always ready to assist our customers with any queries or technical challenges they may encounter.[News Content]Title: Small Linear Stepper Motor Revolutionizing Automation Processes[Location], [Date] - [Company Name], a market leader in automation solutions, has introduced its latest breakthrough product - a small linear stepper motor. This innovative motor has the potential to revolutionize automation processes, offering unparalleled precision and versatility.The small linear stepper motor is designed to provide highly accurate linear motion control in compact applications. Its compact size makes it suitable for a wide range of industries, including medical, electronics, and automotive, among others. The motor offers exceptional repeatability and smooth operation, ensuring optimal performance in even the most demanding applications.One of the key features of the small linear stepper motor is its high resolution. With a resolution of [specify resolution], it enables precise positioning and control, enhancing overall accuracy and efficiency. This level of precision is indispensable in industries that require intricate movements, such as microelectronics manufacturing or medical device assembly.Furthermore, the small linear stepper motor is known for its exceptional speed and acceleration capabilities. It can achieve rapid accelerations, enabling efficient and quick movements, thereby reducing production cycle times. Combined with its compact design, this motor is highly flexible and can be integrated seamlessly into existing automation systems.Unlike traditional linear motors that require complex control systems, the small linear stepper motor simplifies the control process. Its built-in driver and controller eliminate the need for external components, reducing costs and overall system complexity. This plug-and-play functionality ensures easy implementation and reduces the time required for system integration.[Company Name]'s small linear stepper motor also offers robust protection features, ensuring its durability and long lifespan. It incorporates advanced thermal management technology, protecting the motor from overheating and extending its performance. The motor is also designed to withstand harsh environmental conditions, including dust, moisture, and vibration, making it suitable for a wide range of industrial applications."Our small linear stepper motor represents a significant advancement in linear motion control," said [Company Name]'s spokesperson. "Its compact size, high resolution, and exceptional speed make it an ideal choice for various industries. We are excited to provide our customers with a motor that combines cutting-edge technology with ease of use, enhancing their automation processes."As industry demands continue to evolve, [Company Name] reaffirms its commitment to delivering innovative solutions that meet the needs of its customers. The introduction of the small linear stepper motor demonstrates the company's dedication to pushing the boundaries of automation technology, empowering industries to achieve higher levels of productivity and efficiency.In conclusion, [Company Name]'s small linear stepper motor marks a significant milestone in the automation industry. Its compact design, high resolution, and exceptional performance make it a game-changer in precision linear motion control. With its user-friendly features and robust protection, the motor offers a reliable solution for various industries seeking to enhance their automation processes. [Company Name]'s latest innovation reaffirms its position as a leading provider of advanced automation solutions, committed to delivering cutting-edge technologies to its customers worldwide.

How to Choose the Right Gear Motor for Your Needs

Title: Innovative Motor With Gear Revolutionizes the Industrial LandscapeIntroduction (70 words):In an era of breakthrough technological advancements, one company is introducing an innovative motor with gear system that is set to redefine the industrial landscape. With an emphasis on efficiency, reliability, and adaptability, this cutting-edge solution aims to disrupt traditional manufacturing processes. By removing branding, we bring you an unprecedented look at this game-changing technology.Section 1: Background (150 words):In today's fast-paced industrial setting, the demand for high-performance motor systems has never been greater. In response to this market requirement, a renowned company has developed a groundbreaking motor with gear system that is set to boost productivity and enhance overall operational efficiency. With years of research and development, the company has succeeded in combining cutting-edge technology with industry expertise to deliver a holistic and innovative motor-gear solution.Section 2: Key Features and Performance (200 words):The newly unveiled motor with gear system is poised to become a game-changer due to its remarkable features and high-performance capabilities. The system incorporates advanced gear technology that enables seamless power transmission, resulting in enhanced efficiency and reduced energy consumption. Its compact design and lightweight construction ensure easy integration into various applications while maintaining optimal performance.Furthermore, this innovative motor-gear system boasts superior reliability, minimizing downtime and maintenance costs for industrial facilities. The incorporation of state-of-the-art materials and precision engineering results in longevity and durability, making it ideal for continuous operation in rigorous environments.The motor with gear system also offers exceptional adaptability, as it can be custom-designed to meet specific industrial requirements. This flexibility allows manufacturers to optimize the system for their unique applications, leading to improved productivity, precision, and overall output quality.Section 3: Industry Implications and Benefits (200 words):The introduction of this cutting-edge motor with gear system holds significant implications for various industries. From automotive manufacturing to robotics, the innovation is expected to revolutionize traditional processes and streamline operations. By seamlessly integrating into existing manufacturing setups, it offers a cost-effective and efficient solution for businesses.The enhanced efficiency and reliability offered by this motor-gear system also contribute to sustainable practices. With reduced energy consumption and minimized downtime, companies can lower their carbon footprint, making strides toward a greener future. Moreover, enhanced adaptability empowers manufacturers to achieve increased output, while preserving the precision and quality required in modern industries.Section 4: Conclusion (80 words):As industries continue to evolve, the need for transformative solutions becomes paramount. This motor with gear system, developed by an industry-leading company, presents an unparalleled opportunity for manufacturers to optimize their operations, improve product quality, and reduce costs. With its advanced features, exceptional performance, and adaptability, the introduction of this groundbreaking technology is set to redefine the industrial landscape, propelling businesses towards a more efficient and sustainable future.Disclaimer: This news article is a generic representation of a motor with gear system and does not refer to any specific brand.

Top-Notch Medical Stepper Motors for Improved Healthcare Applications

High-Quality Medical Stepper Motors: Revolutionizing the Healthcare IndustryStepper motors are a type of electric motor that has found widespread use in various industries, including healthcare. Specifically, medical stepper motors are a vital component in the development of advanced medical equipment designed to improve patient outcomes. They play a critical role in precision positioning, motion control, and automation in medical devices such as blood analyzers, robotics, ventilators, and other surgical equipment. The demand for high-quality medical stepper motors has never been higher, and companies that specialize in providing these products are working tirelessly to meet the growing demand.One such company that has gained a reputation for its cutting-edge technology in this space is a leading manufacturer of stepper motors for medical equipment. Over the years, they have established themselves as a critical player, providing durable and reliable medical stepper motors that are used in life-saving devices while also meeting the stringent safety regulations required of medical equipment.Their range of stepper motors offers high torque, low noise, and precision performance, making their products an excellent fit for any application medical device. These motors are known for their superior performance, reliability, and durability, making them the top choice for many healthcare equipment manufacturers.Advancements in medical technology are driving continued development of medical devices, and as a result, manufacturers are looking to collaborate with suppliers that can provide key components such as medical stepper motors. The quality of these components can significantly impact the overall performance and safety of the devices. As such, manufacturers are always looking for trusted suppliers to partner with, providing top-of-the-line components with strict adherence to industry standards.As a supplier to the healthcare industry, the company has deep expertise in providing medical stepper motors designed to meet the highest industry standards. The company has developed a vast range of products, from compact and lightweight motors to high-torque and high-torque stepper motors. Each product is engineered to provide smooth, precise, and reliable performance when used in life-sustaining medical equipment. One of the benefits of working with this company is the customization options they offer. Whether the device requires a specific size, power, or torque requirements, their experts can design the ideal solution to meet the specific requirements of the device. They have an in-house development team that can work through the whole process, from initial design stages to final manufacture.Another key benefit of working with this stepper motor manufacturer is their rigorous quality control process. They are committed to ensuring that each product they manufacture meets the highest industry standards and regulatory requirements. They conduct rigorous testing procedures, including vibration and thermal testing, and each motor undergoes a series of quality checks before leaving the factory. This thoroughness gives device manufacturers and end-users peace of mind, knowing that the motors are engineered to perform at the highest level.As use of medical stepper motors becomes increasingly critical in improving medical devices, the importance of selecting a trusted supplier cannot be overstated. It is essential to work with companies that not only provide top-notch products, but also offer ongoing technical support during the life of the device.With over years of experience in designing and manufacturing medical-grade stepper motors, this leading supplier is a trusted partner for healthcare equipment manufacturers. Their dedication to quality, innovation, and customer support is unmatched, ensuring that the medical devices that utilize their motors meet the requirements of the most demanding applications.In conclusion, the healthcare industry never stops advancing, and neither does the demand for top-quality medical devices. Medical stepper motors are a critical component in the development of medical equipment, and as the industry demands innovation and reliability, companies like this one will continue to be critical in providing high-performance motors that meet the industry's demanding requirements. With its commitment to quality and customer satisfaction, it is clear why this organization's medical stepper motors are becoming increasingly popular in the healthcare industry.

New high-performance gearbox motor hits the market

DC Gearbox Motor Shakes Up the IndustryThe DC gearbox motor from (removed brand name) is shaking up the industry with its innovative features and high performance. Designed to meet the needs of various industries, the motor has been built to bring about a significant improvement in efficiency and durability.With a strong focus on research and development, (removed brand name) has been able to create a motor that is suitable for use in numerous applications. The DC gearbox motor has been designed to operate smoothly and efficiently, thanks to its advanced gear reduction mechanism. This unique feature translates into a motor that can provide consistent power output, reducing the wear and tear on the motor and prolonging its lifespan. Furthermore, the DC gearbox motor comes with a wide range of gear ratios, allowing it to be used across different applications.The motor's compact size also makes it an excellent choice for manufacturers looking to maximize space efficiency, without compromising on performance. Manufacturers can now use this motor in tight spaces with ease, while still enjoying the superior performance it offers. This feature also makes the motor suitable for use in equipment that has space constraints, such as robotics and automation.Another unique feature of the DC gearbox motor is its low noise level. The motor has been designed to operate quietly, reducing noise levels and making it ideal for use in applications where noise is a concern. This innovation makes the DC gearbox motor an excellent choice for use in personal care and household appliances, where noise levels are a critical consideration.In addition to the above features, the motor has also been built to withstand harsh operating conditions, making it ideal for use in applications that are exposed to extreme temperatures or high humidity levels. The motor's construction includes high-quality materials, such as stainless steel, which provide protection against environmental factors. The motor has also been designed to be highly resistant to corrosion, making it an excellent choice for use in marine and offshore applications.As a leading manufacturer of motors, (removed brand name) is committed to providing its customers with high-quality products that meet their unique needs. The DC gearbox motor is a testament to this commitment, with its innovative features and high performance. With this motor, manufacturers can now optimize their operations, increase efficiency, and reduce maintenance costs.All in all, the DC gearbox motor from (removed brand name) is an excellent choice for manufacturers looking for a motor that offers superior performance, durability, and efficiency. The motor's innovative features make it the perfect choice for use in numerous applications, while its compact size and low noise level set it apart from other motors in the market. With its robust construction and resistance to harsh operating conditions, the DC gearbox motor is set to revolutionize the motor industry.

Discover the Latest Advancements in 6mm Stepper Motor Technology from China

China 6mm Stepper Motor Leads the Way in Precision and ReliabilityWith the advancement of technology, the demand for precision and reliability in industrial applications has increased significantly. For instance, in medical equipment design, automation, and robotics, the accuracy of motion control is critical. As a result, there has been a need for better-performing motors that can deliver consistent results. This is where China 6mm stepper motor comes in, providing an efficient and reliable solution for precise motion control.The 6mm stepper motor is known for its unique design, which has contributed to its popularity in industrial automation applications. It features a small size that allows it to fit easily into various devices with limited space, yet it can deliver a high level of torque output. This motor has a diameter of only 6mm, making it one of the most compact motor models on the market. However, its small size does not compromise its performance since it can provide excellent torque accuracy and speed control.This stepper motor is versatile, ideal for both single-axis and multi-axis motion control systems. It operates using a precise step-by-step method, which allows it to move with accuracy and consistency. This feature makes it ideal for use in applications that require exact positioning, such as in robotics, 3D printers, and other automated devices.What sets China 6mm stepper motor apart from other stepper motors on the market is its durability and longevity. It is designed with high-quality materials that can withstand harsh environments and operate reliably for an extended period. This means that users can enjoy consistent performance and minimal maintenance costs over the life of the motor.Additionally, this motor comes with varied customization options, making it suitable for different applications. A reputable manufacturer should provide their customers with a range of customization options that perfectly fit their requirements. These range from different windings to shaft configurations, making it an ideal choice for a broad range of applications.The stepper motor features a permanent magnet stepper motor that produces high torque output with less power consumption. It operates using a rotor-stator electromagnetic design, enabling it to provide high torque output and high responsiveness. This design also reduces energy consumption, making it an excellent option for energy-efficient devices.In conclusion, the China 6mm stepper motor is a game-changer in the industrial motor market. Its compact design, accuracy, and reliability make it an ideal choice for applications that require precise motion control. Its durability and longevity make it an excellent investment that will serve its users for years to come. Moreover, its customization options make it fit for various applications, further expanding its use in different sectors. For businesses looking to improve their own production or boost their competitiveness, this motor provides a perfect solution that can boost productivity, reliability, and efficiency.

Small Gear Motors Gain Popularity in Industrial Applications: Report

OEM Mini Gear Motor: Powering Industries WorldwideMini Gear Motors are indispensable components in various industries ranging from automation, healthcare, transportation, and robotics. They come in different sizes, shapes, and torque, but what they all have in common is their ability to deliver reliable and consistent performance. One brand that shines in this category is the OEM Mini Gear Motor.But what is an OEM Mini Gear Motor, and why is it a popular option for many industrial applications? In this article, we will discuss the fundamentals of these gear motors and the advantages of choosing OEM Mini Gear Motor over other brands in the market.Understanding OEM Mini Gear MotorOEM Mini Gear Motor, which we will refer to as OMG moving forward, is a prominent supplier of high-quality mini gear motors. The company specializes in the production of brushed DC and brushless DC gear motors. It was established in 2001 and has since grown into a multidisciplinary firm with offices in various countries worldwide.OMG offers a wide range of mini gear motors with different power and torque ratings. The motors come in three types: planetary, spur, and worm gearboxes. Planetary gearboxes offer the most torque and are ideal for applications that require high precision and control. Spur gearboxes have less torque but are quieter and more efficient. Worm gearboxes offer the least torque but are compact and lightweight, making them suitable for small applications.OMG's mini gear motors are made of high-quality materials that ensure durability and longevity. The motors' housings are made of aluminum or stainless steel, with hardened steel or sintered bronze gears. The bearings are made of high-quality materials, such as ceramic or stainless steel, that can withstand high radial and axial loads.Advantages of Choosing OEM Mini Gear MotorOMG's mini gear motors have several features that set them apart from other brands in the market. Here are some of the advantages of choosing OMG's mini gear motors for your industrial applications:1. High QualityOMG's mini gear motors are made of high-quality materials, ensuring that they are durable and reliable. The motors go through strict quality control measures to ensure that they meet the specifications of the customers and international standards.2. Energy EfficiencyOMG's mini gear motors have a high power-to-size ratio, making them energy-efficient. They have low power consumption, allowing for longer life battery life and reduced environmental impact.3. CustomizableOMG can customize mini gear motors to meet the specific requirements of the customer's application. They offer a range of options, including special motors, gear ratios, and shaft configurations.4. Low NoiseOMG's mini gear motors have a low noise level, making them ideal for use in applications where noise is a concern. The motors are also vibration-free, ensuring that they provide smooth, precise, and consistent performance.5. Cost-effectiveOMG's mini gear motors are competitively priced, making them an affordable option for many industrial applications. They are also easy to install and maintain, reducing the overall cost of ownership.Applications of OEM Mini Gear MotorOMG's mini gear motors are widely used in various industries. Here are some examples of applications that use OMG's mini gear motors:1. RoboticsMini gear motors are used in various types of robotics, such as industrial robots, drones, and humanoid robots. The motors provide precise and consistent motion control, making them ideal for use in applications that require high precision.2. HealthcareMini gear motors are used in various types of medical equipment, such as surgical robots, infusion pumps, and diagnostic equipment. The motors provide accurate and precise control, ensuring that the equipment functions as intended.3. TransportationMini gear motors are used in various types of transportation, such as electric bikes, scooters, and wheelchairs. The motors provide efficient and reliable power, ensuring that the vehicle can travel long distances without frequent recharging.4. AutomationMini gear motors are used in various types of automation, such as conveyor belts, packaging machines, and assembly lines. The motors provide smooth and consistent motion, ensuring that the automation process is efficient and error-free.ConclusionOEM Mini Gear Motor is a leading supplier of high-quality mini gear motors. The company offers a wide range of customizable options, making them ideal for use in various industrial applications. The motors are energy-efficient, low noise, and cost-effective, ensuring that they provide optimal value for money. With their durable and reliable performance, OMG's mini gear motors power industries worldwide.

Newly Developed Planetary Gear Stepper Motor in China Revolutionizes Industry

Title: Chinese Planetary Gear Stepper Motor Revolutionizes Industrial AutomationIntroduction (100 words):China's technology sector continues to make remarkable strides in various industries, and the latest innovation is in the field of industrial automation. Chinese engineers have successfully developed a groundbreaking Planetary Gear Stepper Motor, poised to revolutionize manufacturing and other automated processes. This cutting-edge motor combines precision, reliability, and efficiency to meet the ever-growing demand for advanced automation solutions. With its potential to transform industries globally, experts predict that this Chinese invention will lead the way towards a future of smarter, faster, and more efficient industrial automation.Paragraph 1 (100 words):The Planetary Gear Stepper Motor, manufactured in China, has gained significant attention for its exceptional performance and advanced design. The motor showcases a unique configuration of gears, offering higher torque and smoother movement compared to traditional stepper motors. This breakthrough allows for precise positioning and greater speed control, making it ideal for a wide range of industrial applications. The innovation, combined with China's expertise in manufacturing, has led to a motor that outperforms its competitors, making it a significant player in the global automation market.Paragraph 2 (150 words):One of the key features of the Planetary Gear Stepper Motor is its superior precision. It utilizes a compact arrangement of multiple gears that distribute torque evenly, resulting in increased accuracy and reduced backlash. This enhanced precision ensures greater consistency and reduces the need for manual adjustments. Furthermore, the motor's compact size allows for seamless integration within existing systems, making it a cost-effective solution for retrofitting and upgrading older machinery.Paragraph 3 (150 words):Reliability also takes center stage with the Chinese Planetary Gear Stepper Motor, making it highly suitable for critical industrial applications. Its robust design and optimized gear engagement deliver exceptional durability, enabling continuous operation in demanding environments. The motor's ability to handle heavy loads effortlessly contributes to increased productivity, reduced downtime, and lower maintenance costs. Furthermore, the integration of advanced control technologies allows for precise and efficient motion control, further enhancing its reliability in industrial automation processes.Paragraph 4 (200 words):To sustain China's technological advancement, extensive research and development center around the Planetary Gear Stepper Motor. Chinese companies are heavily invested in continuous improvement and optimization, exploring avenues for increased efficiency and performance. With rising global demand for automation solutions, the Chinese motor manufacturers have committed significant resources towards expanding their production capacities and meeting market needs.Paragraph 5 (150 words):The adoption of the Chinese Planetary Gear Stepper Motor extends beyond manufacturing into various industries such as robotics, aerospace, and medical equipment. The motor's versatility, combined with its precise positioning and exceptional reliability, makes it an ideal choice for sophisticated applications. The motor's exceptional performance has caught the attention of international companies seeking reliable and cost-effective automation solutions. As a result, China's Planetary Gear Stepper Motor has gained a competitive edge in the global market, challenging the dominance of established players.Conclusion (50 words):China's groundbreaking Planetary Gear Stepper Motor demonstrates the country's technological prowess in industrial automation. With its exceptional precision, reliability, and versatility, the motor presents an ideal solution for various sectors worldwide. As China continues to invest in research and development, it is poised to become a global leader in advanced automation technologies.