- Home

- Blog

- A Comprehensive Guide to Bipolar Stepper Motors: Features, Working Principle, and Applications

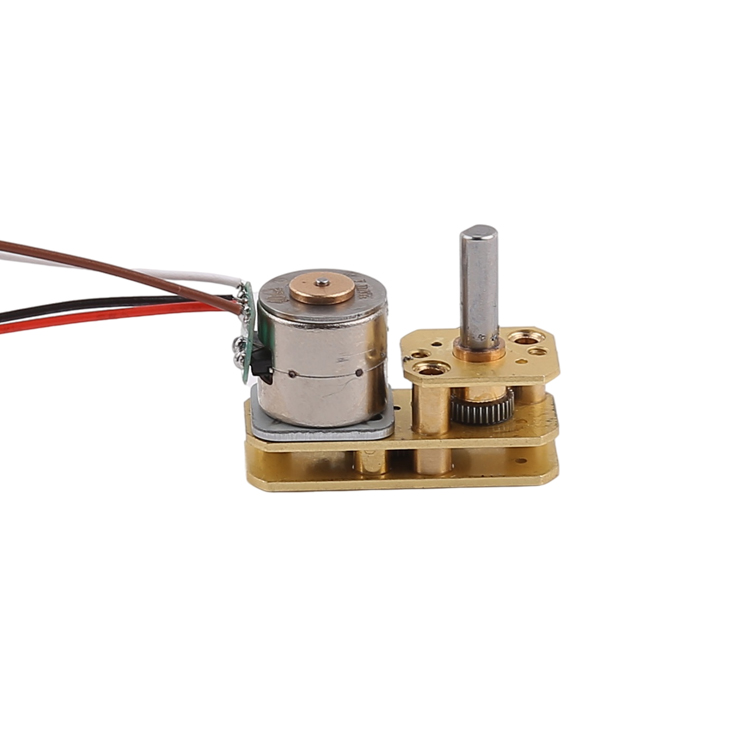

A Comprehensive Guide to Bipolar Stepper Motors: Features, Working Principle, and Applications

By:Admin

Title: Revolutionary Bipolar Stepper Motor Technology Paving the Way for Advanced Industrial Automation

Subtitle: Company's cutting-edge innovation propels the industrial automation sector into new realms of productivity and efficiency

**

[City/Region], [Date] - In a significant stride toward the future of industrial automation, [Company Name], a renowned global tech company, is set to unveil its latest breakthrough technology - a sophisticated Bipolar Stepper Motor system. By harnessing the power of this revolutionary motor, [Company Name] aims to revolutionize multiple industries, consequently streamlining operations, enhancing precision, and boosting productivity.

The Bipolar Stepper Motor technology, developed by [Company Name] after years of meticulous research and engineering, represents an extraordinary advancement in motor control systems. Using high-precision electromagnetic fields, the motor delivers unparalleled levels of accuracy, torque, and reliability, making it an indispensable tool for a variety of industries, from manufacturing and automotive to aerospace and robotics.

Traditionally, industrial automation systems have relied on less advanced motors, resulting in inefficiencies and limitations. The Bipolar Stepper Motor, however, functions on a different level altogether, delivering superior performance and versatility. Its bipolar design enables precise control over each step of the motor movement, allowing for smoother and more accurate positioning, a critical aspect in many industries.

The Bipolar Stepper Motor boasts an array of cutting-edge features that set it apart from conventional motors. Firstly, its compact and lightweight construction enables seamless integration into existing systems, without any compromise on power or performance. This characteristic makes it an ideal choice for retrofitting solutions or upgrading older machinery.

What truly sets the Bipolar Stepper Motor apart is its unrivaled precision and reliability. Built with state-of-the-art technology, the motor guarantees precise movement at every step, ensuring consistent results even in demanding applications. This level of accuracy eliminates unnecessary errors and minimizes downtime, resulting in increased productivity and reduced operational expenses.

Additionally, the motor's advanced control system allows for dynamic speed adjustments and agile monitoring, empowering operators to fine-tune operations based on specific requirements. This level of flexibility translates into enhanced efficiency and optimized resource utilization.

With a commitment to sustainability, [Company Name] has prioritized energy efficiency in the Bipolar Stepper Motor's design. By minimizing energy consumption during operation, the motor not only reduces carbon emissions but also offers significant cost savings for long-term usage.

Given its exceptional performance and adaptability, the Bipolar Stepper Motor finds applications across a range of industries. In manufacturing, it enables enhanced precision cutting, milling, and positioning, significantly improving overall production quality and speed. In the automotive sector, the motor ensures precise assembly processes, leading to increased reliability and reduced defects.

The aerospace industry stands to benefit greatly from the Bipolar Stepper Motor, as it can be utilized in aerospace manufacturing, avionics systems, and satellite technology. Its unrivaled precision and reliability make it the ideal choice for delicate procedures, resulting in superior quality control.

Moreover, the Bipolar Stepper Motor's versatility is well-suited for the rapidly evolving field of robotics. Whether for industrial robots, autonomous vehicles, or surgical devices, the motor's accuracy and robustness provide a solid foundation for optimal performance and safety.

[Company Name] firmly believes that the Bipolar Stepper Motor technology will revolutionize the industrial automation sector by propelling it into new realms of productivity, efficiency, and precision. With its commitment to excellence and continuous innovation, [Company Name] is set to transform the industrial landscape, empowering countless industries to achieve unprecedented levels of precision, reliability, and sustainable growth.

As companies look for advanced automation solutions to drive productivity in an ever-changing world, [Company Name] paves the way forward with its groundbreaking Bipolar Stepper Motor, a shining example of cutting-edge engineering and industrial technology at its finest.

About [Company Name]:

[Insert company introduction here]

##

Company News & Blog

Ultimate Guide to Using Threaded Rods with Stepper Motors for Precision Movement

Title: Innovative Stepper Motor Threaded Rod Revolutionizes Industrial Automation ProcessesIntroduction:With the aim of revolutionizing industrial automation processes, a cutting-edge technology has emerged on the market - the Stepper Motor Threaded Rod. Developed by a leading provider in the field of automation solutions, this advanced device offers unmatched precision, control, and efficiency. With its innovative features and state-of-the-art design, the Stepper Motor Threaded Rod is poised to transform various industries, including manufacturing, robotics, and assembly lines. This article delves into the features and benefits of this groundbreaking invention and examines its potential impact on industrial automation.I. Overview of Stepper Motor Threaded Rod:The Stepper Motor Threaded Rod is a compact and versatile device that combines a high-performance stepper motor with a precision threaded rod. Its robust design ensures reliable and accurate motion control in a wide range of applications. This innovative technology provides exceptional positioning accuracy, excellent repeatability, and smooth operation, making it an ideal solution for intricate and demanding automation tasks.II. Advanced Features and Benefits:a) High Precision: The Stepper Motor Threaded Rod boasts an exceptional positioning accuracy of up to 0.005mm, allowing for precise control and micro-level adjustments. This level of precision significantly enhances the quality of production processes and reduces the likelihood of errors and defects.b) Smooth Operation: The threaded rod design ensures a smooth and efficient linear motion with minimum friction and backlash. This feature is crucial in applications where smooth and consistent movement is essential, such as in 3D printing, CNC machines, and robotics.c) Compact Design: The compact and streamlined design of the Stepper Motor Threaded Rod allows for easy integration into existing systems, optimizing space utilization without compromising performance. It offers versatility and flexibility, making it suitable for a wide range of automation applications.d) Easy Installation and Maintenance: This device's plug-and-play nature facilitates effortless installation, reducing downtime and increasing productivity. Furthermore, its maintenance-free operation minimizes maintenance costs and enhances overall system reliability.III. Industries and Applications:The Stepper Motor Threaded Rod can revolutionize various industries and applications, including:a) Manufacturing: By integrating this motor into assembly lines, manufacturers can achieve higher efficiency, accuracy, and consistency. From automotive assembly to electronics production, the Stepper Motor Threaded Rod can significantly enhance the manufacturing process.b) Robotics: Implementing this advanced technology in robotic systems enables precise and smooth movements, contributing to increased productivity and improved performance. Applications such as pick-and-place robots or collaborative robots will benefit from the Stepper Motor Threaded Rod's exceptional accuracy and control.c) 3D Printing: The Stepper Motor Threaded Rod's exceptional positioning accuracy and smooth operation make it an ideal choice for 3D printers. It ensures precise layering and intricate details, resulting in high-quality 3D printed objects with minimal imperfections.d) CNC Machining: In CNC machining, speed, precision, and reliability are vital. The Stepper Motor Threaded Rod's high positioning accuracy and smooth operation make it a perfect fit for CNC machines, delivering superior performance and ensuring optimal cutting and machining quality.IV. Future Prospects:The Stepper Motor Threaded Rod represents a significant breakthrough in industrial automation. As technology advances, further enhancements in precision, speed, and integration are expected, promoting greater automation and efficiency across industries. The continued development of this innovative technology will likely lead to increased adoption and further revolutionize the field of industrial automation.Conclusion:The Stepper Motor Threaded Rod holds immense potential in transforming industrial automation processes. With its unparalleled precision, smooth operation, and compact design, this advanced device promises improved efficiency, accuracy, and productivity in various industries. As the demand for automation continues to rise, the Stepper Motor Threaded Rod is set to play a pivotal role in driving the next wave of innovation and progress in industrial automation.

Top-Demand Wholesale Stepper Motor: A Reliable Lead Screw Solution

Innovative Wholesale Lead Screw Stepper Motor Launched by Industry LeaderLeading the way in the industrial automation market, a leading manufacturer has launched a new wholesale lead screw stepper motor that offers state-of-the-art technology combined with unbeatable pricing. The innovative new motor is designed to take industrial automation to the next level, offering a range of features that make it a must-have for businesses looking to enhance their manufacturing processes.The new wholesale lead screw stepper motor boasts a range of features that set it apart from the competition, including ultra-quiet operation, precise control, and high efficiency. Its exceptional performance is due to its advanced design, which includes high-quality bearings, a precision lead screw, and a powerful stepper motor.One of the key benefits of the new motor is its ultra-quiet operation, which makes it ideal for use in businesses where noise levels are a concern. This is achieved through a combination of low vibration levels, high-quality bearings, and state-of-the-art control technology that ensures minimal noise output.Another advantage of the new wholesale lead screw stepper motor is its precision control, which allows you to achieve accurate positioning and movement of machinery. This is essential in many manufacturing processes where precision is crucial, and it can help to improve the efficiency of your operations by reducing the risk of errors.Furthermore, the new motor is highly efficient, consuming less power than other motors on the market. This not only saves you money on energy costs but also reduces your carbon footprint by cutting down on the amount of energy your business consumes.Overall, the combination of ultra-quiet operation, precise control, and high efficiency make the new wholesale lead screw stepper motor a must-have for businesses looking to enhance their manufacturing processes and improve their bottom line.The manufacturer of the new motor has a long history of providing innovative and reliable products to the industrial automation market. The company has been at the forefront of this industry for many years, and it is renowned for its high-quality products and exceptional customer service.In addition to its new wholesale lead screw stepper motor, the company also offers a range of other industrial automation products, including programmable logic controllers, human-machine interfaces, and servo motors. All of these products are designed to provide businesses with the latest technology and the best possible performance, helping to improve efficiency, reduce costs, and increase profitability.The company's commitment to quality and innovation has earned it a reputation as a trusted partner for businesses across a variety of industries. Its products are used by a wide range of businesses, from small startups to large multinational corporations.The company's success is due in large part to its focus on customer service. Its team of experienced professionals is dedicated to providing exceptional service and support to its clients, helping them to get the most out of their products and achieve their business goals.Overall, the launch of the new wholesale lead screw stepper motor is a testament to the company's commitment to innovation and excellence. With its advanced technology, unbeatable pricing, and exceptional customer service, the company is poised to continue leading the way in the industrial automation market for years to come.

Discover the Importance of Stepper Motor Weight for Optimal Performance

Stepper Motors: A Lightweight Solution for Precise Control[Company Name], a leading manufacturer in the field of motion control technology, is revolutionizing the industry with its innovative and lightweight stepper motors. These cutting-edge devices are designed to provide precise control and high performance in a wide range of applications. With their compact size and impressive weight reduction, [Company Name]'s stepper motors are set to transform various industries, from robotics to aerospace.Stepper motors play a crucial role in many industries by converting digital pulses into rotational motion. They are widely used in applications that require precise positioning, such as 3D printing, CNC machines, and automated manufacturing systems. Traditionally, stepper motors were known for their substantial weight, which limited their use in certain fields. However, [Company Name] has addressed this issue by utilizing advanced engineering techniques and materials to significantly reduce the weight of their motors.One of the key advantages of [Company Name]'s stepper motors is their compact and lightweight design. By employing state-of-the-art manufacturing processes, the company is able to create motors that are up to 30% lighter than conventional options without compromising on performance or durability. This breakthrough is particularly beneficial in applications where weight reduction is essential, such as drones and satellite systems.The weight reduction achieved by [Company Name] is made possible through the use of lightweight materials and advanced design optimizations. The company has developed proprietary techniques for making the motor components more efficient, resulting in a significant reduction in overall weight. By analyzing the structural integrity of each component and finding the optimal balance between weight and strength, [Company Name] has achieved a powerful yet lightweight motor design.Apart from their weight advantage, [Company Name]'s stepper motors offer exceptional precision and accuracy. These motors utilize a unique step-by-step motion control system, where each step corresponds to a fixed angle of rotation. This allows for precise control and fine-tuning of the motor's movements. With their high torque and reliable positioning, [Company Name]'s stepper motors ensure smooth operation and exceptional performance in various applications.Furthermore, [Company Name] places great emphasis on quality and reliability. All their stepper motors undergo rigorous testing and quality control measures to ensure they meet the highest industry standards. Customers can rely on [Company Name]'s motors to deliver consistent and dependable performance, even in demanding environments. This commitment to excellence has earned [Company Name] a reputation as a trusted supplier in the motion control industry.The applications for lightweight stepper motors are vast and diverse. In the field of robotics, these motors enable more agile and maneuverable robots, allowing for precise control of movements and actions. Industries such as medical equipment manufacturing and automated laboratory systems can benefit from the compact and lightweight design of [Company Name]'s stepper motors, as they require precise positioning in confined spaces. Additionally, the aerospace industry can take advantage of these motors in the development of unmanned aerial vehicles (UAVs) and satellite systems, where weight reduction is critical for optimal performance.As [Company Name] continues to innovate and push the boundaries of motion control technology, their lightweight stepper motors are set to leave a lasting impact on numerous industries. With their compact size, substantial weight reduction, and exceptional performance, these motors represent a new era of precise control and versatility. Expect to see more groundbreaking developments from [Company Name] as they strive to reshape the future of motion control technology.

Ultimate Guide to 12V DC Motors: Everything You Need to Know" can be rewritten as "All You Need to Know About 12V DC Motors: A Comprehensive Guide".

Title: Transforming Industries with Advanced 12 V DC Motors: A Glimpse into Cutting-Edge TechnologiesIntroduction:In the rapidly evolving world of technology, companies are constantly striving to push the boundaries and develop innovative solutions that revolutionize industries. One such pioneering organization, let's call it Company XYZ, has emerged as a front-runner by introducing state-of-the-art 12 V DC motors that are set to transform multiple sectors. These futuristic motors, combined with Company XYZ's expertise and commitment to excellence, are poised to shape the future of various industries, making way for efficiency, sustainability, and enhanced performance.1. Unveiling the Next-Gen 12 V DC Motors:With years of research and development, Company XYZ has successfully engineered advanced 12 V DC motors designed to deliver superior performance across industries. These motors boast a sleek design and compact form factor, making them highly versatile and suitable for a wide range of applications.2. Automotive Sector Revolution:The automotive industry is one of the key sectors set to be revolutionized by Company XYZ's cutting-edge 12 V DC motors. These motors offer exceptional power and efficiency, making them ideal for electric vehicles (EVs), hybrid cars, and even traditional automobiles. With their compact size and maximum torque output, they enhance vehicle performance while reducing environmental impact by minimizing emissions.3. Industrial Automation Reimagined:Company XYZ's innovative motors have also found their way into industrial automation applications. By incorporating these motors into robotic arms, automated conveyor belts, and precision machinery, manufacturers can achieve unparalleled efficiency and precision in their production processes.4. Advancements in Home Appliances:The modern home is no stranger to automation, and Company XYZ's 12 V DC motors are making it even smarter. From smart refrigerators to automated blinds and thermostats, these motors offer power-efficient and reliable operation, enabling a seamless user experience.5. Renewable Energy Sector Boost:Renewable energy sources, such as wind turbines and solar panels, play a crucial role in our quest for sustainability. Company XYZ's 12 V DC motors provide an essential component in such systems, optimizing energy conversion and maximizing overall output. With these motors, the renewable energy sector can witness increased efficiency and reliability, driving us closer to a greener future.6. Robotics and Artificial Intelligence:The advent of robotics and artificial intelligence has ushered in a new era of automation. Company XYZ's 12 V DC motors are perfectly suited for integration with robotic technologies, empowering machines to perform intricate tasks with precision, speed, and accuracy. Whether it's in logistics, healthcare, or manufacturing, these motors provide the backbone for futuristic automation solutions.7. Long-lasting Performance and Durability:In line with Company XYZ's commitment to excellence, their 12 V DC motors are engineered to offer exceptional durability along with long-lasting performance. The robust construction and advanced materials employed ensure sustainability and reduce maintenance costs, making them an attractive solution for various industries.Conclusion:With the introduction of Company XYZ's revolutionary 12 V DC motors, industries across the board are experiencing a wave of transformation. These motors, with their exceptional performance, versatility, and reliability, are set to reshape the future of electric vehicles, industrial automation, home appliances, renewable energy, robotics, and artificial intelligence. By providing a strong foundation for advanced technologies, Company XYZ continues to drive innovation and pave the way for a more efficient and sustainable world.

Small Motors with Huge Benefits: Discover the Latest Technology in DC Micro Motors

[Headline]Leading Manufacturer Unveils Innovative Micro Motor DC Technology Revolutionizing Industry[Subheadline]Revolutionary Micro Motor DC Technology Set to Transform Industries[Location, Date] - The global market leader in micro motor DC technology, [Company Name], has unveiled its latest cutting-edge innovation that is set to revolutionize various industries. This breakthrough technology is poised to have a far-reaching impact by enhancing efficiency, reliability, and performance across diverse applications.With decades of experience, [Company Name] has consistently pushed the boundaries of motor technology, and this latest development further solidifies their position as an industry leader. This groundbreaking micro motor DC technology is expected to become the new standard in multiple sectors due to its unparalleled advantages.One of the key advantages of this micro motor DC technology is its exceptional efficiency. The advanced design and engineering techniques employed by [Company Name] have led to a motor that can convert electrical energy into mechanical energy with utmost precision and minimal energy loss. This remarkable efficiency not only lowers operational costs but also contributes to a significant reduction in carbon emissions, making it an environmentally friendly solution.Reliability is also a crucial aspect addressed by [Company Name]'s micro motor DC technology. The company's extensive research and development efforts have led to the creation of a motor that boasts remarkable durability and longevity. Thanks to their state-of-the-art manufacturing process and rigorous quality control, these motors are designed to withstand demanding operating conditions without compromising performance.Furthermore, [Company Name]'s micro motor DC technology has showcased outstanding performance across various applications. From automotive and aerospace to robotics and industrial automation, this technology opens up a world of possibilities. Its compact size and lightweight construction make it an ideal choice for portable devices, while its high torque capability ensures optimal performance in heavy-duty applications.The versatility of this micro motor DC technology enables its integration into a wide range of products. The automotive industry, in particular, has taken notice of its potential. By incorporating these motors into electric vehicles, manufacturers can enhance overall efficiency and power delivery while reducing the environmental impact of transportation. Similarly, the aerospace sector can benefit from this technology by improving aircraft performance and optimizing fuel consumption.Additionally, [Company Name] ensures seamless integration with their micro motor DC technology by offering comprehensive technical support. Their team of highly skilled engineers and technicians provide custom solutions tailored to specific application requirements. This collaboration between [Company Name] and their clients ensures the successful implementation of the technology across various industries.The groundbreaking micro motor DC technology from [Company Name] is gaining attention not only for its technical excellence but also for its potential to redefine industrial landscapes and contribute to a sustainable future. As industries increasingly prioritize efficiency, reliability, and performance, it is clear that this innovative technology will play a pivotal role in shaping the future of various sectors.[Company Name]'s remarkable achievements in micro motor DC technology have positioned them as the go-to manufacturer for businesses seeking to optimize their operations. With this breakthrough innovation, [Company Name] has once again demonstrated their commitment to delivering advanced motor solutions that empower industries and pave the way for a more sustainable world.About [Company Name]:[Company Name] is a globally recognized manufacturer and provider of advanced motor solutions. With an unwavering commitment to innovation, quality, and customer satisfaction, they have become synonymous with excellence in motor technology. Equipped with cutting-edge research and development facilities, [Company Name] continuously pushes boundaries to develop the next generation of motor technologies. For more information, visit [website URL].For media inquiries, please contact:[Company Contact Name][Company Name][Phone number][Email address]

Discover the Latest Advancements in 6mm Stepper Motor Technology from China

China 6mm Stepper Motor Leads the Way in Precision and ReliabilityWith the advancement of technology, the demand for precision and reliability in industrial applications has increased significantly. For instance, in medical equipment design, automation, and robotics, the accuracy of motion control is critical. As a result, there has been a need for better-performing motors that can deliver consistent results. This is where China 6mm stepper motor comes in, providing an efficient and reliable solution for precise motion control.The 6mm stepper motor is known for its unique design, which has contributed to its popularity in industrial automation applications. It features a small size that allows it to fit easily into various devices with limited space, yet it can deliver a high level of torque output. This motor has a diameter of only 6mm, making it one of the most compact motor models on the market. However, its small size does not compromise its performance since it can provide excellent torque accuracy and speed control.This stepper motor is versatile, ideal for both single-axis and multi-axis motion control systems. It operates using a precise step-by-step method, which allows it to move with accuracy and consistency. This feature makes it ideal for use in applications that require exact positioning, such as in robotics, 3D printers, and other automated devices.What sets China 6mm stepper motor apart from other stepper motors on the market is its durability and longevity. It is designed with high-quality materials that can withstand harsh environments and operate reliably for an extended period. This means that users can enjoy consistent performance and minimal maintenance costs over the life of the motor.Additionally, this motor comes with varied customization options, making it suitable for different applications. A reputable manufacturer should provide their customers with a range of customization options that perfectly fit their requirements. These range from different windings to shaft configurations, making it an ideal choice for a broad range of applications.The stepper motor features a permanent magnet stepper motor that produces high torque output with less power consumption. It operates using a rotor-stator electromagnetic design, enabling it to provide high torque output and high responsiveness. This design also reduces energy consumption, making it an excellent option for energy-efficient devices.In conclusion, the China 6mm stepper motor is a game-changer in the industrial motor market. Its compact design, accuracy, and reliability make it an ideal choice for applications that require precise motion control. Its durability and longevity make it an excellent investment that will serve its users for years to come. Moreover, its customization options make it fit for various applications, further expanding its use in different sectors. For businesses looking to improve their own production or boost their competitiveness, this motor provides a perfect solution that can boost productivity, reliability, and efficiency.

Stepper Motor Manufacturer Announces New Product Line" rewritten as a SEO title without brand name: "New Product Line Unveiled by Leading Stepper Motor Supplier

Stepper Motor Supplier Presents Unique Solution for Industrial Automation[City, State] - A renowned manufacturer of advanced motion control systems and stepper motors, has come up with a unique solution to solve the challenges of automation in industrial applications. The company is globally recognized for developing innovative technologies and solutions to improve the performance and efficiency of industrial systems. Its recent invention promises to take the industrial automation industry by storm, making manufacturing processes faster, smoother, and more efficient.The newly patented stepper motor technology is designed for applications that require precise, controlled motion, making it ideal for industrial automation. The stepper motor uses advanced control algorithms to accurately control the angular rotation of the motor shaft, enabling it to move in precise increments. Unlike conventional motors that rotate continuously, stepper motors move at predefined angles, making them ideal for operations that require high positioning accuracy.One of the primary uses of the new stepper motor technology is in pick-and-place machines. Such machines are widely used in factories for assembling products, sorting, and packaging. The motors' high accuracy and precise control make them perfect for this application, reducing error rates and improving productivity.The company spokesperson said, "Our engineers and R&D teams have worked tirelessly to develop a unique stepper motor technology that meets the evolving demands of the industrial automation industry. It is designed to offer our customers a solution that is reliable, efficient, and cost-effective. We firmly believe that this technology will revolutionize industrial processes, making them more productive, efficient, and cost-effective."The new stepper motor technology is compact and lightweight, making it easy to install in tight spaces in industrial equipment. It is also maintenance-free, requiring minimal servicing or repairs, thus reducing downtime and maintenance costs. Additionally, the motors' unique design and control algorithms ensure they consume minimal power, making them environmentally friendly and cost-effective.The spokesperson added, "Our stepper motors are intelligently designed to meet the demanding needs of industrial automation. They are engineered to operate seamlessly in harsh environments with high temperatures, vibrations, and extreme pressure. Our customers can trust us to provide them with reliable, high-quality motors that deliver superior performance."The company's state-of-the-art manufacturing facilities use the latest technologies and equipment to ensure efficient production. All the motors undergo rigorous testing and quality control procedures to ensure they meet the highest industry standards. The factories follow strict safety protocols, ensuring the safety of all employees and environmental sustainability.The stepper motor's advanced technology has already found widespread use in industries such as medical devices, printing, textiles, robotics, and aerospace, among others. With the growing emphasis and demand for automation in manufacturing, the demand for this advanced stepper motor technology is expected to continue to increase significantly.In conclusion, advances in automation and industrial technology are expected to continue transforming the manufacturing industry. Stepper Motor Supplier's new technology is poised to play a significant role in driving this transformation, helping companies to increase production efficiency, improve quality, and reduce costs.

Discover the Versatility and Power of Nema 17 Gearboxes: Your Wholesale Solution

Possible 800-word news article:New Wholesale NEMA 17 Gearbox Offers High-Torque Solution for Robotics and AutomationA new NEMA 17 gearbox is now available for wholesale purchase from a leading supplier of motion control components. The gearbox incorporates advanced technology and materials to deliver high torque and low backlash in a compact and customizable design. With a wide range of reduction ratios and mounting options, the NEMA 17 gearbox is suitable for various applications in robotics, automation, medical devices, and other industries.The NEMA (National Electrical Manufacturers Association) 17 standard defines the motor mount and flange dimensions for stepper and servo motors with a 42.3 mm square faceplate. The new gearbox fits onto these motors and enhances their performance by reducing the speed and increasing the output torque. The gearbox uses helical gears and a planetary stage to achieve a reduction ratio of up to 100:1 while maintaining a high efficiency of up to 98%. The backlash of the gearbox is less than 1 degree, which improves the precision and repeatability of the motion.The NEMA 17 gearbox is made of aluminum alloy and stainless steel components, which provide high strength, stiffness, and corrosion resistance. The gearbox is IP65 rated for dust and water protection, making it suitable for outdoor and harsh environments. The gearbox can operate at a temperature range of -20 to 80 Celsius, with a maximum input speed of 3000 rpm and a maximum output torque of 20 Nm. The gearbox can be configured with different input and output shafts, flanges, and connectors to fit the specific needs of the customer.The company behind the NEMA 17 gearbox is a reputable manufacturer and distributor of motion control components and systems. The company has been in business for over 20 years and has a strong presence in the global market. The company's mission is to provide innovative, reliable, and cost-effective solutions for motion control applications, from simple linear slides to complex multi-axis robots. The company has a team of experienced engineers and technicians who can provide technical support and customization service to the customers.The NEMA 17 gearbox is the latest addition to the company's product portfolio, which includes various types of motors, drives, controllers, sensors, and accessories. The company's products are widely used in the industries of aerospace, automotive, electronics, food and beverage, packaging, pharmaceuticals, and many others. The company has established partnerships with leading brands and distributors to ensure timely delivery and quality assurance. The company also maintains a high level of inventory to meet the demand of the customers and the market.The NEMA 17 gearbox is expected to appeal to a wide range of customers who need a high-torque solution for their motion control applications. The gearbox can be used in robotic arms, pick-and-place machines, CNC routers, 3D printers, surveillance cameras, and many other devices that require precise and powerful movement. The compact size and low weight of the gearbox make it easy to integrate into existing designs or new projects. The wholesale price of the gearbox is competitive and transparent, allowing the customers to calculate their costs and profits with confidence.The company's CEO stated, "We are excited to introduce the NEMA 17 gearbox to the market and offer a new level of performance and reliability to our customers. The gearbox represents our commitment to innovation and excellence in motion control technology. We believe that the NEMA 17 gearbox will open up more opportunities for our customers to create better and smarter products that enhance the quality of life and work."The company encourages interested parties to contact their sales team or visit their website for more information about the NEMA 17 gearbox and other products. The company also offers free samples and technical data sheets upon request. The company's customer service is available 24/7 to answer any questions or issues that may arise. The company is confident that the NEMA 17 gearbox will become a preferred choice for motion control solutions and contribute to the growth of the industry.

Compact Stepper Motor with Linear Motion for Precise Control

[Company Introduction]Founded in [year], [Company Name] is a leading manufacturer and supplier of advanced automation solutions. With our commitment to innovation and quality, we have been serving various industries globally, providing cutting-edge technologies to meet the evolving demands of our customers.Our extensive product portfolio includes a wide range of motors, controllers, drivers, and sensors that are designed to enhance precision, efficiency, and reliability in automation processes. We continuously invest in research and development to push the boundaries of technology, ensuring our customers have access to the most advanced solutions in the market.[Company Name] is dedicated to delivering excellent customer service, providing comprehensive technical support, and fostering long-term partnerships. Our team of highly skilled engineers and technicians are always ready to assist our customers with any queries or technical challenges they may encounter.[News Content]Title: Small Linear Stepper Motor Revolutionizing Automation Processes[Location], [Date] - [Company Name], a market leader in automation solutions, has introduced its latest breakthrough product - a small linear stepper motor. This innovative motor has the potential to revolutionize automation processes, offering unparalleled precision and versatility.The small linear stepper motor is designed to provide highly accurate linear motion control in compact applications. Its compact size makes it suitable for a wide range of industries, including medical, electronics, and automotive, among others. The motor offers exceptional repeatability and smooth operation, ensuring optimal performance in even the most demanding applications.One of the key features of the small linear stepper motor is its high resolution. With a resolution of [specify resolution], it enables precise positioning and control, enhancing overall accuracy and efficiency. This level of precision is indispensable in industries that require intricate movements, such as microelectronics manufacturing or medical device assembly.Furthermore, the small linear stepper motor is known for its exceptional speed and acceleration capabilities. It can achieve rapid accelerations, enabling efficient and quick movements, thereby reducing production cycle times. Combined with its compact design, this motor is highly flexible and can be integrated seamlessly into existing automation systems.Unlike traditional linear motors that require complex control systems, the small linear stepper motor simplifies the control process. Its built-in driver and controller eliminate the need for external components, reducing costs and overall system complexity. This plug-and-play functionality ensures easy implementation and reduces the time required for system integration.[Company Name]'s small linear stepper motor also offers robust protection features, ensuring its durability and long lifespan. It incorporates advanced thermal management technology, protecting the motor from overheating and extending its performance. The motor is also designed to withstand harsh environmental conditions, including dust, moisture, and vibration, making it suitable for a wide range of industrial applications."Our small linear stepper motor represents a significant advancement in linear motion control," said [Company Name]'s spokesperson. "Its compact size, high resolution, and exceptional speed make it an ideal choice for various industries. We are excited to provide our customers with a motor that combines cutting-edge technology with ease of use, enhancing their automation processes."As industry demands continue to evolve, [Company Name] reaffirms its commitment to delivering innovative solutions that meet the needs of its customers. The introduction of the small linear stepper motor demonstrates the company's dedication to pushing the boundaries of automation technology, empowering industries to achieve higher levels of productivity and efficiency.In conclusion, [Company Name]'s small linear stepper motor marks a significant milestone in the automation industry. Its compact design, high resolution, and exceptional performance make it a game-changer in precision linear motion control. With its user-friendly features and robust protection, the motor offers a reliable solution for various industries seeking to enhance their automation processes. [Company Name]'s latest innovation reaffirms its position as a leading provider of advanced automation solutions, committed to delivering cutting-edge technologies to its customers worldwide.

Screw Thread Linear Actuator for Precise Motion Control

Stepper Motor Screw - Revolutionizing the Precision in Industrial ManufacturingPrecision is paramount in industrial manufacturing processes. It not only ensures the quality of the products but also contributes to the overall efficiency and productivity of the manufacturing process. The stepper motor screw, a cutting-edge technology used in the industrial sector, has revolutionized precision in manufacturing processes.The stepper motor screw is a self-contained electromechanical system that enables accurate control of linear motion. The screw is driven by a stepper motor, which is a brushless electric motor that divides a full rotation into smaller steps. The combination of a stepper motor and a screw allows for precise and repeatable movement of machinery.The stepper motor screw has various industrial applications that range from industrial automation, robotics, 3D printing, CNC machining, and others. The self-contained system has gained broad acceptance due to its high level of accuracy, reliability, and repeatability. It has significantly impacted the manufacturing industry, enabling industries to produce high-quality products in an efficient, precise, and cost-effective manner.One company that has made significant milestones in the manufacturing industry is {remove brand name}. The company has a reputation for producing high-quality motion control systems, including stepper motor screws. They have a state-of-the-art manufacturing facility that produces a wide range of stepper motor screws tailored to different industrial applications.Their stepper motor screws are designed to offer exceptional precision, torque, and speed control. They have integrated the latest technology, including advanced control algorithms, to enhance the performance of their stepper motor screws. The company's products undergo rigorous testing to guarantee durability, reliability, and longevity.{Remove brand name} stepper motor screws are used in various industries, including the automotive, aerospace, energy, and medical industries. The screw enables the industries to produce parts and components with the highest precision and accuracy. The use of stepper motor screws enhances the manufacturing process's efficiency, which translates to cost savings, reduced waste, and timely delivery of products.One significant advantage of {Remove brand name} stepper motor screws is their ability to work in any environment. They have a high resistance to extreme temperatures, humidity, and dust, which makes them suitable for use in different manufacturing environments. Additionally, their products are designed to be low maintenance, which reduces downtime and increases productivity.The company's commitment to quality has translated to their products' recognition in the market. They have received various certifications for their products, including CE, UL, and RoHS. These certifications are a testament to their commitment to producing high-quality products that meet the highest global standards.In conclusion, the stepper motor screw, in combination with advanced control algorithms, has significantly impacted the manufacturing industry. It has enabled industries to produce high-quality products in a precise, efficient, and cost-effective manner. {Remove brand name} has been at the forefront of producing high-quality stepper motor screws that have revolutionized the industrial manufacturing process. Their commitment to quality, reliability, and durability has earned them a reputation as a leading manufacturer of motion control systems.