Top-Demand Wholesale Stepper Motor: A Reliable Lead Screw Solution

By:Admin

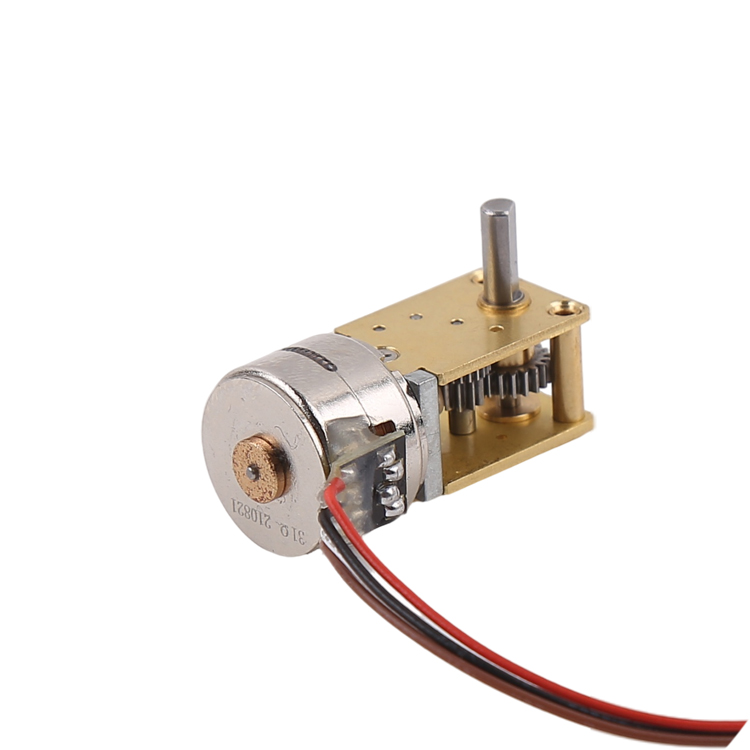

Leading the way in the industrial automation market, a leading manufacturer has launched a new wholesale lead screw stepper motor that offers state-of-the-art technology combined with unbeatable pricing. The innovative new motor is designed to take industrial automation to the next level, offering a range of features that make it a must-have for businesses looking to enhance their manufacturing processes.

The new wholesale lead screw stepper motor boasts a range of features that set it apart from the competition, including ultra-quiet operation, precise control, and high efficiency. Its exceptional performance is due to its advanced design, which includes high-quality bearings, a precision lead screw, and a powerful stepper motor.

One of the key benefits of the new motor is its ultra-quiet operation, which makes it ideal for use in businesses where noise levels are a concern. This is achieved through a combination of low vibration levels, high-quality bearings, and state-of-the-art control technology that ensures minimal noise output.

Another advantage of the new wholesale lead screw stepper motor is its precision control, which allows you to achieve accurate positioning and movement of machinery. This is essential in many manufacturing processes where precision is crucial, and it can help to improve the efficiency of your operations by reducing the risk of errors.

Furthermore, the new motor is highly efficient, consuming less power than other motors on the market. This not only saves you money on energy costs but also reduces your carbon footprint by cutting down on the amount of energy your business consumes.

Overall, the combination of ultra-quiet operation, precise control, and high efficiency make the new wholesale lead screw stepper motor a must-have for businesses looking to enhance their manufacturing processes and improve their bottom line.

The manufacturer of the new motor has a long history of providing innovative and reliable products to the industrial automation market. The company has been at the forefront of this industry for many years, and it is renowned for its high-quality products and exceptional customer service.

In addition to its new wholesale lead screw stepper motor, the company also offers a range of other industrial automation products, including programmable logic controllers, human-machine interfaces, and servo motors. All of these products are designed to provide businesses with the latest technology and the best possible performance, helping to improve efficiency, reduce costs, and increase profitability.

The company's commitment to quality and innovation has earned it a reputation as a trusted partner for businesses across a variety of industries. Its products are used by a wide range of businesses, from small startups to large multinational corporations.

The company's success is due in large part to its focus on customer service. Its team of experienced professionals is dedicated to providing exceptional service and support to its clients, helping them to get the most out of their products and achieve their business goals.

Overall, the launch of the new wholesale lead screw stepper motor is a testament to the company's commitment to innovation and excellence. With its advanced technology, unbeatable pricing, and exceptional customer service, the company is poised to continue leading the way in the industrial automation market for years to come.

Company News & Blog

New High-Performance Gear Ratio Diameter Enhances Industrial Efficiency in China

Title: China's Latest Gear Ratio Diameter Revolutionizes Industrial ProcessesIntroduction:China, at the forefront of technological advancements, has introduced a groundbreaking gear ratio diameter that is set to redefine industrial processes. With a strong focus on innovation and cutting-edge manufacturing capabilities, Chinese companies have led the way in developing this game-changing gear technology. By efficiently maximizing power transmission, optimizing system performance, and improving overall productivity, this innovation is poised to catapult Chinese industries into a new era of growth and competitiveness. Gear Ratio Diameter: Revolutionizing Industrial Efficiency:The recently developed gear ratio diameter holds immense potential to revolutionize industrial efficiency across various sectors. Backed by extensive research and development, this gear technology is designed to enhance power transmission efficiency, reduce energy consumption, and ensure high levels of precision in industrial applications. Chinese manufacturing companies have duly acknowledged the importance of gear systems in enhancing overall productivity. Through the implementation of this gear ratio diameter, businesses can drive improvements in processes that rely on power transmission, such as automotive manufacturing, heavy machinery production, marine propulsion, and many others. This technology allows for the customization of gear systems to optimize torque requirements, resulting in significant cost savings and greater operational efficiencies.Furthermore, this advanced gear technology boasts the ability to minimize friction, reduce noise levels, and improve overall gear system performance. With better gear synchronization, industries can expect reduced downtime, enhanced reliability, and increased machine longevity. The Competitive Edge:China, being one of the global leaders in manufacturing, has recognized the significance of investing in innovative technologies to solidify its competitive edge. Chinese companies have transformed their gear manufacturing capabilities to ensure that the gear ratio diameter fulfills the dynamic needs of industries both nationally and internationally. By making use of advanced manufacturing techniques, such as CNC machining, automation, and precise quality control processes, Chinese manufacturers have achieved unparalleled levels of precision in gear production. This precision is crucial for the successful implementation of the gear ratio diameter, as even minor deviations can compromise the efficiency and performance of the system.Moreover, Chinese manufacturers have also focused on applying high-quality materials and rigorous testing processes to ensure the durability and longevity of their gear systems. This commitment to quality has allowed Chinese companies to gain the trust of domestic and international customers, solidifying their position as reliable suppliers of gear transmission solutions.Global Adaptation:The introduction of the gear ratio diameter technology by Chinese companies has received global attention and acclaim. Many international businesses, including those operating in developed countries with established industrial sectors, are recognizing the immense benefits of incorporating this gear technology into their operations.The ease of adaptability and customization provided by the gear ratio diameter technology is a key factor that attracts businesses from all corners of the globe. By offering tailor-made gear systems, Chinese manufacturers can accommodate specific industrial requirements, ensuring maximum efficiency and performance for each unique application.Additionally, the cost-effectiveness of these gear systems also appeals to international businesses. With Chinese manufacturers offering competitive pricing without compromising on quality, foreign industries can achieve significant cost savings while embracing cutting-edge technology.Future Outlook:Looking ahead, the development and implementation of the gear ratio diameter technology will continue to drive China's industrial growth and development. With a strong commitment to investing in research and development, Chinese manufacturers are poised to push the boundaries of gear technology even further.As industries across the globe seek ways to boost efficiency and productivity, Chinese gear systems are poised to become an essential component of their operations, ensuring seamless power transmission and maximum reliability. Chinese manufacturers will likely continue to innovate and refine gear systems to meet evolving industry demands and cement their position as leaders in the worldwide market.Conclusion:China's gear ratio diameter technology represents a significant milestone in the industrial sector. Its ability to optimize power transmission, enhance precision, reduce energy consumption, and provide cost-effective solutions has made it highly sought after globally. Backed by Chinese manufacturers' commitment to quality, adaptability, and manufacturing excellence, this gear technology is set to shape the future of industrial processes, positioning China at the forefront of global manufacturing innovation and competitiveness.

Discover the Optimum Gear Ratio Diameter You Need for ODM Equipment

ODM Gear Ratio Diameter Revolutionizes Manufacturing ProcessInnovation drives progress, and the manufacturing industry is no exception. Today, ODM Gear Ratio Diameter (GRD) is leading the charge in revolutionizing the manufacturing process in various industries. With their cutting-edge technology and advanced gear solutions, ODM is streamlining manufacturing processes, improving efficiency, and maximizing output.ODM GRD is a brand of gear solutions that combines the best in design, engineering, and manufacturing. The gear solutions offered by ODM are innovative, reliable, and customizable to fit the needs of clients from various industries such as aerospace, automotive, energy, and defense. Additionally, ODM keeps the process of customizing these solutions simple, so that clients can focus on their end products.With its headquarters and state-of-the-art research facility in Southern California, ODM Gear Ratio Diameter has been in the business of manufacturing gears since 1993. It is a subsidiary of a designing and manufacturing enterprise called Origin International Inc, which has been around for over four decades. This experience and expertise can be seen in the quality of ODM's gears and the satisfaction of their clients.What distinguishes ODM GRD from other solutions is the gear ratio diameter, which is the heart of their products. Gear ratio diameter, in simple terms, is the relative sizes of the gears' pitch diameters that mesh with one another. This ratio determines the gear's speed, torque, and efficiency. ODM's GRD technology allows for optimized gear ratio diameter, which translates into more output efficiency, extended operational life, and reduced wear and tear.ODM gear solutions have been tested and proven to meet the highest industry standards for precision, strength, and durability. These solutions are designed with state-of-the-art software and manufactured with the most advanced materials, such as high-quality alloys and heat-treated steels. Additionally, ODM gear solutions come in different styles and types, from parallel shaft to bevel gears, depending on specific client needs.ODM's GRD technology enhances manufacturing processes in several ways. For example, in the aerospace industry, precise gear solutions are essential to ensure the safe and efficient operation of aircraft systems. ODM's custom gear solutions provide design flexibility, optimal transmission efficiency, and Enhanced Load Distribution (ELD) which reduces stress, increases output and lifespan, and improves safety.In the automotive industry, ODM gear solutions play a vital role in the transmission system. The gear solutions' performance, quality, and durability are critical to ensure that the vehicle runs smoothly and efficiently. ODM customizes gear solutions for clients based on their specific vehicle type, size, performance, and efficiency requirements.In the energy sector, ODM provides its gear solutions to oil and gas drilling rigs, wind turbines, and solar power plants. These solutions optimize the power generation and transmission processes by offering high-torque, high-efficiency, and high-performance gear solutions. Additionally, these solutions reduce maintenance costs and improve the overall operational life of the equipment.In the defense industry, ODM gear solutions provide unmatched strength, durability, and precision. These solutions are designed to withstand the most extreme conditions and provide maximum efficiency in critical operations, such as the drivetrains in armored vehicles and weaponry. In such situations, failure is not an option, and ODM's gear solutions offer reliability and safety to military personnel in the field.In conclusion, ODM Gear Ratio Diameter is revolutionizing the manufacturing industry with its advanced gear solutions. With customized gears that deliver enhanced efficiency, extended operational life, and reduced wear and tear, ODM is enabling clients to drive innovation and growth in their respective industries. ODM GRD technology is changing the game, and the company's commitment to quality, reliability, and service is cementing its position as a leader in the gear manufacturing industry.

Discover the Versatility and Power of Nema 17 Gearboxes: Your Wholesale Solution

Possible 800-word news article:New Wholesale NEMA 17 Gearbox Offers High-Torque Solution for Robotics and AutomationA new NEMA 17 gearbox is now available for wholesale purchase from a leading supplier of motion control components. The gearbox incorporates advanced technology and materials to deliver high torque and low backlash in a compact and customizable design. With a wide range of reduction ratios and mounting options, the NEMA 17 gearbox is suitable for various applications in robotics, automation, medical devices, and other industries.The NEMA (National Electrical Manufacturers Association) 17 standard defines the motor mount and flange dimensions for stepper and servo motors with a 42.3 mm square faceplate. The new gearbox fits onto these motors and enhances their performance by reducing the speed and increasing the output torque. The gearbox uses helical gears and a planetary stage to achieve a reduction ratio of up to 100:1 while maintaining a high efficiency of up to 98%. The backlash of the gearbox is less than 1 degree, which improves the precision and repeatability of the motion.The NEMA 17 gearbox is made of aluminum alloy and stainless steel components, which provide high strength, stiffness, and corrosion resistance. The gearbox is IP65 rated for dust and water protection, making it suitable for outdoor and harsh environments. The gearbox can operate at a temperature range of -20 to 80 Celsius, with a maximum input speed of 3000 rpm and a maximum output torque of 20 Nm. The gearbox can be configured with different input and output shafts, flanges, and connectors to fit the specific needs of the customer.The company behind the NEMA 17 gearbox is a reputable manufacturer and distributor of motion control components and systems. The company has been in business for over 20 years and has a strong presence in the global market. The company's mission is to provide innovative, reliable, and cost-effective solutions for motion control applications, from simple linear slides to complex multi-axis robots. The company has a team of experienced engineers and technicians who can provide technical support and customization service to the customers.The NEMA 17 gearbox is the latest addition to the company's product portfolio, which includes various types of motors, drives, controllers, sensors, and accessories. The company's products are widely used in the industries of aerospace, automotive, electronics, food and beverage, packaging, pharmaceuticals, and many others. The company has established partnerships with leading brands and distributors to ensure timely delivery and quality assurance. The company also maintains a high level of inventory to meet the demand of the customers and the market.The NEMA 17 gearbox is expected to appeal to a wide range of customers who need a high-torque solution for their motion control applications. The gearbox can be used in robotic arms, pick-and-place machines, CNC routers, 3D printers, surveillance cameras, and many other devices that require precise and powerful movement. The compact size and low weight of the gearbox make it easy to integrate into existing designs or new projects. The wholesale price of the gearbox is competitive and transparent, allowing the customers to calculate their costs and profits with confidence.The company's CEO stated, "We are excited to introduce the NEMA 17 gearbox to the market and offer a new level of performance and reliability to our customers. The gearbox represents our commitment to innovation and excellence in motion control technology. We believe that the NEMA 17 gearbox will open up more opportunities for our customers to create better and smarter products that enhance the quality of life and work."The company encourages interested parties to contact their sales team or visit their website for more information about the NEMA 17 gearbox and other products. The company also offers free samples and technical data sheets upon request. The company's customer service is available 24/7 to answer any questions or issues that may arise. The company is confident that the NEMA 17 gearbox will become a preferred choice for motion control solutions and contribute to the growth of the industry.

Medical Stepper Motor Now Available for Enhanced Medical Equipment Performance

ODM Company Launches Revolutionary Medical Stepper Motor with Cutting-Edge TechnologyODM, a leading manufacturer of advanced electronic equipment, has launched their latest creation in the world of medical technology: their revolutionary new medical stepper motor. This state-of-the-art invention features cutting-edge technology designed to meet the most demanding needs of medical professionals in a variety of fields.With its compact design, precision engineering and reliable performance, the ODM medical stepper motor is ideal for a broad range of medical applications, such as imaging, diagnostic testing, surgical equipment, and more. Its powerful motor provides precise, controlled movement that enables medical practitioners to work with greater accuracy and speed, while its advanced features make it easy to install, use and maintain.Engineered for SuccessThe ODM medical stepper motor is engineered for success, with the latest technology designed to deliver superior performance and reliability. Its high torque, low-to-mid range speed, and exceptional accuracy make it the perfect choice for a variety of medical applications, including robotics, imaging, and diagnostic systems.One of the key features of the ODM medical stepper motor is its compact size, which makes it ideal for use in small, space-constrained medical devices. The motor's low profile design, combined with its lightweight construction, means that it can be easily integrated into a variety of medical equipment without adding excess weight or consuming valuable space.An ideal choice for medical professionals looking for an accurate and reliable motor, the ODM medical stepper motor is highly precise, with a step angle accuracy of over +3% (full step) and +5% (half step). This means that it can provide highly accurate, repeatable motion control, even in the most demanding medical applications.Another key feature of the ODM medical stepper motor is its advanced electromagnetic compatibility (EMC) system, which provides superior noise suppression and improves performance in even the most electrically noisy environments. This makes it ideal for use in medical applications with high levels of electromagnetic interference.Reliable, Durable DesignThe ODM medical stepper motor is also designed to be highly reliable and durable, with a lifespan of over one million cycles. This makes it an ideal choice for medical professionals who require a stepper motor that can perform accurately and consistently over a long period of time.The motor's durable construction, combined with its advanced features, also makes it easy to install, use and maintain. It features a simple, compact design that can be easily integrated into a variety of medical devices, and requires minimal maintenance to keep it performing at optimal levels.At ODM, we take pride in the quality of our products, and our medical stepper motor is no exception. We understand that medical professionals require precise, reliable equipment to perform their jobs effectively, and we have designed our medical stepper motor to meet these exacting standards.In addition to its powerful performance, the ODM medical stepper motor is also designed with safety in mind, featuring advanced safety features that help ensure it operates safely and reliably in even the most challenging medical applications.Meeting the Needs of Medical ProfessionalsAt ODM, we are committed to meeting the needs of medical professionals in a broad range of fields. Our new medical stepper motor is designed with these professionals in mind, providing the precise, reliable performance they need to carry out their important work.With its compact size, powerful performance and advanced features, the ODM medical stepper motor is an ideal choice for medical professionals who demand the best from their equipment. Whether you are working in imaging, diagnostic testing, surgical equipment, or robotics, this revolutionary new motor will meet all your needs and exceed your expectations.In a world where medical technology is advancing faster than ever before, the ODM medical stepper motor is setting the standard for reliability, accuracy and performance. Trust ODM to provide the equipment you need to help you perform vital work in the medical field.

How to Calculate Gear Ratio Using Diameter Measurements

Title: Next Generation Gear Ratio Diameter Revolutionizes Manufacturing IndustryIntroduction:In an era driven by technological advancements and innovation, companies across various sectors are constantly on the lookout for superior solutions to improve their production processes. One such breakthrough gaining traction is the implementation of a new gear ratio diameter technology, which is set to revolutionize the manufacturing industry. By optimizing performance, reducing costs, and increasing efficiency, this cutting-edge gear ratio diameter technology promises to reshape the future of manufacturing.The Functionality Behind Gear Ratio Diameter Technology:Gear ratio diameter refers to the relationship between the size of a gear and the gear's tooth count, which affects the overall performance of machinery. The introduction of this latest gear technology aims to enhance the efficiency of mechanical systems by reimagining the gear's ratio and diameter to match specific requirements. By leveraging advanced engineering techniques and materials, this technology optimizes power transmission and reduces friction, resulting in heightened performance and increased durability.Key Benefits of Gear Ratio Diameter Technology:1. Increased Efficiency: By incorporating this gear technology, manufacturers can achieve a higher degree of efficiency in their mechanical systems. The precise calibration of gear ratios and diameters enables smoother and more seamless power transmission, reducing energy losses and increasing overall equipment efficiency.2. Cost Reduction: This innovative gear technology eliminates the need for unnecessary component customization and specialized machining processes. The standardized gear ratios and diameters streamline production and reduce costs, making this technology an ideal choice for manufacturers aiming to enhance productivity while minimizing manufacturing expenses.3. Enhanced Durability: The implementation of this cutting-edge gear technology ensures the longevity and reliability of machinery. With its optimized gear ratios and diameters, friction and wear are significantly reduced, resulting in extended product lifespan and reduced maintenance requirements.4. Versatile Applications: Gear ratio diameter technology has vast potential across industries, ranging from automotive and aerospace to robotics and industrial equipment. Its versatility allows manufacturers to optimize their processes and offer products capable of seamlessly integrating with various applications, thereby widening their market reach and increasing their business opportunities.Company XYZ's Contribution to Gear Ratio Diameter Technology:XYZ, a renowned engineering company dedicated to pushing the boundaries of innovation, has emerged as a leader in the development and implementation of gear ratio diameter technology. Their team of skilled engineers and researchers have extensively studied the intricate relationship between gear ratios, diameters, and performance optimization. XYZ's commitment to continuous improvement has resulted in revolutionary gear designs that maximize efficiency while offering unparalleled durability.XYZ's gear ratio diameter technology is meticulously crafted and standardized to align with different industrial requirements. Their precise calibration and attention to detail ensure optimal power transmission, reduced friction, and enhanced overall system performance. By leveraging this cutting-edge technology, manufacturers can better meet customer expectations by providing superior products that surpass industry standards.Conclusion:As manufacturing companies strive to stay ahead in a competitive market, gear ratio diameter technology emerges as a game-changer. The use of optimized gear ratios and diameters offers increased efficiency, reduced costs, and enhanced durability for a wide array of applications. With industry leaders like XYZ pioneering this technology, the manufacturing industry can embrace a future that is both technologically advanced and economically efficient.

Small Motors with Huge Benefits: Discover the Latest Technology in DC Micro Motors

[Headline]Leading Manufacturer Unveils Innovative Micro Motor DC Technology Revolutionizing Industry[Subheadline]Revolutionary Micro Motor DC Technology Set to Transform Industries[Location, Date] - The global market leader in micro motor DC technology, [Company Name], has unveiled its latest cutting-edge innovation that is set to revolutionize various industries. This breakthrough technology is poised to have a far-reaching impact by enhancing efficiency, reliability, and performance across diverse applications.With decades of experience, [Company Name] has consistently pushed the boundaries of motor technology, and this latest development further solidifies their position as an industry leader. This groundbreaking micro motor DC technology is expected to become the new standard in multiple sectors due to its unparalleled advantages.One of the key advantages of this micro motor DC technology is its exceptional efficiency. The advanced design and engineering techniques employed by [Company Name] have led to a motor that can convert electrical energy into mechanical energy with utmost precision and minimal energy loss. This remarkable efficiency not only lowers operational costs but also contributes to a significant reduction in carbon emissions, making it an environmentally friendly solution.Reliability is also a crucial aspect addressed by [Company Name]'s micro motor DC technology. The company's extensive research and development efforts have led to the creation of a motor that boasts remarkable durability and longevity. Thanks to their state-of-the-art manufacturing process and rigorous quality control, these motors are designed to withstand demanding operating conditions without compromising performance.Furthermore, [Company Name]'s micro motor DC technology has showcased outstanding performance across various applications. From automotive and aerospace to robotics and industrial automation, this technology opens up a world of possibilities. Its compact size and lightweight construction make it an ideal choice for portable devices, while its high torque capability ensures optimal performance in heavy-duty applications.The versatility of this micro motor DC technology enables its integration into a wide range of products. The automotive industry, in particular, has taken notice of its potential. By incorporating these motors into electric vehicles, manufacturers can enhance overall efficiency and power delivery while reducing the environmental impact of transportation. Similarly, the aerospace sector can benefit from this technology by improving aircraft performance and optimizing fuel consumption.Additionally, [Company Name] ensures seamless integration with their micro motor DC technology by offering comprehensive technical support. Their team of highly skilled engineers and technicians provide custom solutions tailored to specific application requirements. This collaboration between [Company Name] and their clients ensures the successful implementation of the technology across various industries.The groundbreaking micro motor DC technology from [Company Name] is gaining attention not only for its technical excellence but also for its potential to redefine industrial landscapes and contribute to a sustainable future. As industries increasingly prioritize efficiency, reliability, and performance, it is clear that this innovative technology will play a pivotal role in shaping the future of various sectors.[Company Name]'s remarkable achievements in micro motor DC technology have positioned them as the go-to manufacturer for businesses seeking to optimize their operations. With this breakthrough innovation, [Company Name] has once again demonstrated their commitment to delivering advanced motor solutions that empower industries and pave the way for a more sustainable world.About [Company Name]:[Company Name] is a globally recognized manufacturer and provider of advanced motor solutions. With an unwavering commitment to innovation, quality, and customer satisfaction, they have become synonymous with excellence in motor technology. Equipped with cutting-edge research and development facilities, [Company Name] continuously pushes boundaries to develop the next generation of motor technologies. For more information, visit [website URL].For media inquiries, please contact:[Company Contact Name][Company Name][Phone number][Email address]

Top-Demand Wholesale Stepper Motor: A Reliable Lead Screw Solution

Innovative Wholesale Lead Screw Stepper Motor Launched by Industry LeaderLeading the way in the industrial automation market, a leading manufacturer has launched a new wholesale lead screw stepper motor that offers state-of-the-art technology combined with unbeatable pricing. The innovative new motor is designed to take industrial automation to the next level, offering a range of features that make it a must-have for businesses looking to enhance their manufacturing processes.The new wholesale lead screw stepper motor boasts a range of features that set it apart from the competition, including ultra-quiet operation, precise control, and high efficiency. Its exceptional performance is due to its advanced design, which includes high-quality bearings, a precision lead screw, and a powerful stepper motor.One of the key benefits of the new motor is its ultra-quiet operation, which makes it ideal for use in businesses where noise levels are a concern. This is achieved through a combination of low vibration levels, high-quality bearings, and state-of-the-art control technology that ensures minimal noise output.Another advantage of the new wholesale lead screw stepper motor is its precision control, which allows you to achieve accurate positioning and movement of machinery. This is essential in many manufacturing processes where precision is crucial, and it can help to improve the efficiency of your operations by reducing the risk of errors.Furthermore, the new motor is highly efficient, consuming less power than other motors on the market. This not only saves you money on energy costs but also reduces your carbon footprint by cutting down on the amount of energy your business consumes.Overall, the combination of ultra-quiet operation, precise control, and high efficiency make the new wholesale lead screw stepper motor a must-have for businesses looking to enhance their manufacturing processes and improve their bottom line.The manufacturer of the new motor has a long history of providing innovative and reliable products to the industrial automation market. The company has been at the forefront of this industry for many years, and it is renowned for its high-quality products and exceptional customer service.In addition to its new wholesale lead screw stepper motor, the company also offers a range of other industrial automation products, including programmable logic controllers, human-machine interfaces, and servo motors. All of these products are designed to provide businesses with the latest technology and the best possible performance, helping to improve efficiency, reduce costs, and increase profitability.The company's commitment to quality and innovation has earned it a reputation as a trusted partner for businesses across a variety of industries. Its products are used by a wide range of businesses, from small startups to large multinational corporations.The company's success is due in large part to its focus on customer service. Its team of experienced professionals is dedicated to providing exceptional service and support to its clients, helping them to get the most out of their products and achieve their business goals.Overall, the launch of the new wholesale lead screw stepper motor is a testament to the company's commitment to innovation and excellence. With its advanced technology, unbeatable pricing, and exceptional customer service, the company is poised to continue leading the way in the industrial automation market for years to come.

Top Gear Motors for All Your Industrial Needs - An Overview

Wholesale Gear Motors embarks on mission to provide quality products at affordable pricesIn a world where technology is king and innovation is paramount, the demand for efficient and high-performance machinery has increased tenfold. With the rise of mechanization, the need for a more robust and reliable power source has become a top priority for many industries.Wholesale Gear Motors, a reputable provider of geared motors in the market, has taken the initiative to provide a solution to this problem. As one of the leading gear motor suppliers, the company has been supplying top-grade geared motors to various industries for over a decade. Known for their quality products and unparalleled customer service, the company has embarked on a mission to provide premium equipment at affordable prices.The company's mission is to become a leading supplier of geared motors, while keeping their prices affordable to a wide range of businesses. The Wholesome Gear Motors product line is designed with custom solutions that cater to different industries and their specific needs. The company's products are known for their efficiency, durability, and reliability, making them a top choice for many businesses.One of the factors that makes Wholesale Gear Motors stand out in the market is their exceptional product quality. The company adheres to strict quality standards, ensuring that every gear motor that leaves its manufacturing facility is of top-notch quality. They use the latest technology and advanced manufacturing processes to produce their products, ensuring maximum efficiency and reliability.In addition to their quality products, the company also strives to provide unparalleled customer service. The company's team of experts is always available to answer any questions customers may have about their products. They work closely with clients to understand their unique needs and offer custom solutions to cater to their specific requirements.One of the company's key strengths is their ability to offer cost-effective solutions to their clients. The company has always strived to keep their prices low, without sacrificing the quality of their products. Their commitment to delivering affordable products without compromising on quality has helped them gain the trust of many customers.Wholesale Gear Motors has also made it a priority to expand their product portfolio. The company offers a wide range of geared motors, including worm gear motors, helical gear motors, and planetary gear motors. They also offer customized solutions, catering to unique client needs.Recently, the company launched a new range of gear motors that are designed to meet the specific needs of the food and beverage industry. The motors are built with food-grade materials, ensuring that they are safe for use in various food and beverage applications.In conclusion, Wholesale Gear Motors is a leading provider of geared motors in the market. They have built a solid reputation for themselves through their quality products, affordable prices, and exceptional customer service. The company's commitment to delivering efficient and reliable gear motors that are affordable to a wide range of businesses has made them a top choice for many industries. With their focus on innovation and superior product quality, Wholesale Gear Motors is set to become a leading supplier of geared motors in the industry.

Stepper Motor Manufacturer Announces New Product Line" rewritten as a SEO title without brand name: "New Product Line Unveiled by Leading Stepper Motor Supplier

Stepper Motor Supplier Presents Unique Solution for Industrial Automation[City, State] - A renowned manufacturer of advanced motion control systems and stepper motors, has come up with a unique solution to solve the challenges of automation in industrial applications. The company is globally recognized for developing innovative technologies and solutions to improve the performance and efficiency of industrial systems. Its recent invention promises to take the industrial automation industry by storm, making manufacturing processes faster, smoother, and more efficient.The newly patented stepper motor technology is designed for applications that require precise, controlled motion, making it ideal for industrial automation. The stepper motor uses advanced control algorithms to accurately control the angular rotation of the motor shaft, enabling it to move in precise increments. Unlike conventional motors that rotate continuously, stepper motors move at predefined angles, making them ideal for operations that require high positioning accuracy.One of the primary uses of the new stepper motor technology is in pick-and-place machines. Such machines are widely used in factories for assembling products, sorting, and packaging. The motors' high accuracy and precise control make them perfect for this application, reducing error rates and improving productivity.The company spokesperson said, "Our engineers and R&D teams have worked tirelessly to develop a unique stepper motor technology that meets the evolving demands of the industrial automation industry. It is designed to offer our customers a solution that is reliable, efficient, and cost-effective. We firmly believe that this technology will revolutionize industrial processes, making them more productive, efficient, and cost-effective."The new stepper motor technology is compact and lightweight, making it easy to install in tight spaces in industrial equipment. It is also maintenance-free, requiring minimal servicing or repairs, thus reducing downtime and maintenance costs. Additionally, the motors' unique design and control algorithms ensure they consume minimal power, making them environmentally friendly and cost-effective.The spokesperson added, "Our stepper motors are intelligently designed to meet the demanding needs of industrial automation. They are engineered to operate seamlessly in harsh environments with high temperatures, vibrations, and extreme pressure. Our customers can trust us to provide them with reliable, high-quality motors that deliver superior performance."The company's state-of-the-art manufacturing facilities use the latest technologies and equipment to ensure efficient production. All the motors undergo rigorous testing and quality control procedures to ensure they meet the highest industry standards. The factories follow strict safety protocols, ensuring the safety of all employees and environmental sustainability.The stepper motor's advanced technology has already found widespread use in industries such as medical devices, printing, textiles, robotics, and aerospace, among others. With the growing emphasis and demand for automation in manufacturing, the demand for this advanced stepper motor technology is expected to continue to increase significantly.In conclusion, advances in automation and industrial technology are expected to continue transforming the manufacturing industry. Stepper Motor Supplier's new technology is poised to play a significant role in driving this transformation, helping companies to increase production efficiency, improve quality, and reduce costs.

New high-performance gearbox motor hits the market

DC Gearbox Motor Shakes Up the IndustryThe DC gearbox motor from (removed brand name) is shaking up the industry with its innovative features and high performance. Designed to meet the needs of various industries, the motor has been built to bring about a significant improvement in efficiency and durability.With a strong focus on research and development, (removed brand name) has been able to create a motor that is suitable for use in numerous applications. The DC gearbox motor has been designed to operate smoothly and efficiently, thanks to its advanced gear reduction mechanism. This unique feature translates into a motor that can provide consistent power output, reducing the wear and tear on the motor and prolonging its lifespan. Furthermore, the DC gearbox motor comes with a wide range of gear ratios, allowing it to be used across different applications.The motor's compact size also makes it an excellent choice for manufacturers looking to maximize space efficiency, without compromising on performance. Manufacturers can now use this motor in tight spaces with ease, while still enjoying the superior performance it offers. This feature also makes the motor suitable for use in equipment that has space constraints, such as robotics and automation.Another unique feature of the DC gearbox motor is its low noise level. The motor has been designed to operate quietly, reducing noise levels and making it ideal for use in applications where noise is a concern. This innovation makes the DC gearbox motor an excellent choice for use in personal care and household appliances, where noise levels are a critical consideration.In addition to the above features, the motor has also been built to withstand harsh operating conditions, making it ideal for use in applications that are exposed to extreme temperatures or high humidity levels. The motor's construction includes high-quality materials, such as stainless steel, which provide protection against environmental factors. The motor has also been designed to be highly resistant to corrosion, making it an excellent choice for use in marine and offshore applications.As a leading manufacturer of motors, (removed brand name) is committed to providing its customers with high-quality products that meet their unique needs. The DC gearbox motor is a testament to this commitment, with its innovative features and high performance. With this motor, manufacturers can now optimize their operations, increase efficiency, and reduce maintenance costs.All in all, the DC gearbox motor from (removed brand name) is an excellent choice for manufacturers looking for a motor that offers superior performance, durability, and efficiency. The motor's innovative features make it the perfect choice for use in numerous applications, while its compact size and low noise level set it apart from other motors in the market. With its robust construction and resistance to harsh operating conditions, the DC gearbox motor is set to revolutionize the motor industry.